filmov

tv

Threadlocker Removal

Показать описание

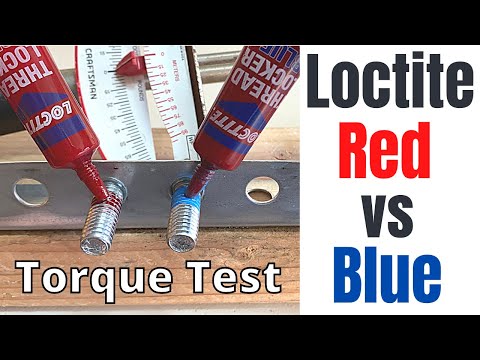

In the last episode, we talked about thread locker 101. The different types of compounds, how to apply it and when to use the different types.

Following up, we are now going over threadlocker removal. How to remove screws and fasteners that have been secured with thread locking compound. Some can be more difficult than others but using the techniques shown in this video you shouldn't have any issues. Thanks for watching!

Social Links:

- - Note for YouTube: The portions of this video featuring the firing of a firearm were conducted at a specified range facility in a controlled, safe environment under the direction of instructors or range safety officers. Any assembly or disassembly is for the purposes of showing safe and proper repair or maintenance. ALL OF OUR CONTENT IS IN COMPLIANCE WITH YOUR AD CERTIFICATION POLICY.

- The views and opinions expressed in this video are solely those of the original authors and contributors. These views and opinions do not necessarily represent those of Guns & Tactics, the administrative staff, and/or any/all contributors to this site.

- Affiliate Disclaimer: Guns and Tactics is reader/viewer supported. This post may contain affiliate links and we may earn a small commission when you click on the links at no additional cost to you. As an Amazon Affiliate I earn from qualifying purchases.

Following up, we are now going over threadlocker removal. How to remove screws and fasteners that have been secured with thread locking compound. Some can be more difficult than others but using the techniques shown in this video you shouldn't have any issues. Thanks for watching!

Social Links:

- - Note for YouTube: The portions of this video featuring the firing of a firearm were conducted at a specified range facility in a controlled, safe environment under the direction of instructors or range safety officers. Any assembly or disassembly is for the purposes of showing safe and proper repair or maintenance. ALL OF OUR CONTENT IS IN COMPLIANCE WITH YOUR AD CERTIFICATION POLICY.

- The views and opinions expressed in this video are solely those of the original authors and contributors. These views and opinions do not necessarily represent those of Guns & Tactics, the administrative staff, and/or any/all contributors to this site.

- Affiliate Disclaimer: Guns and Tactics is reader/viewer supported. This post may contain affiliate links and we may earn a small commission when you click on the links at no additional cost to you. As an Amazon Affiliate I earn from qualifying purchases.

Комментарии

0:01:16

0:01:16

0:08:55

0:08:55

0:09:38

0:09:38

0:03:03

0:03:03

0:01:40

0:01:40

0:02:16

0:02:16

0:01:05

0:01:05

0:03:05

0:03:05

0:09:23

0:09:23

0:03:24

0:03:24

0:02:39

0:02:39

0:05:52

0:05:52

0:01:36

0:01:36

0:00:30

0:00:30

0:06:00

0:06:00

0:05:35

0:05:35

0:00:25

0:00:25

0:15:38

0:15:38

0:09:24

0:09:24

0:04:20

0:04:20

0:01:59

0:01:59

0:03:36

0:03:36

0:04:32

0:04:32

0:07:40

0:07:40