filmov

tv

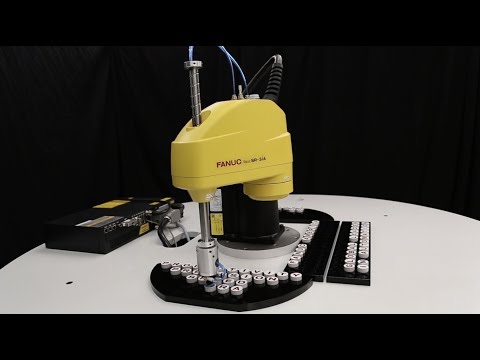

Micro Robot Arm Precision Test

Показать описание

What are some good tests to apply to this robot arm? We want to figure out whether or not the thing is working the way we think it is working. For example, we think there are no missed steps, but is this really true? The robot arm operates open loop. There are no rotary encoders involved. The microcontroller keeps track of the current positions of all the joints by counting the pulses that are getting sent to the stepper driver chips. The motors might slip and lose a step. And even if the motors are moving reliably, is the microcontroller counting the steps correctly? There might be a bug in the software.

We need data. So let's check how precise the robot arm is able to move. In the video below, the robot arm moves in a fixed manner. We mark 2 positions; One to check mainly for errors along the Y-Axis, another position for errors along the X-Axis.

The results show that the position used to check deviations along the Y-Axis got lower over time (the robot arm was moving for 5 minutes in total), while the error along the X-Axis seemed small. Since the error is in the same direction as the earth's gravitational pull, this might indicate that there indeed were some missed steps. But one could also argue that the precision is within margins considering the gears backlash is about 2.5°. It also seemed like the error was converging to some certain amount.

More time had to be invested to pin down the cause/causes of the error seen in this video. Since it is moving fairly accurate I call it a day. The next project's waiting!

Buy the 12V 28BYJ-48 stepper motors used in this project on Amazon (Affiliated link):

Read more here:

We need data. So let's check how precise the robot arm is able to move. In the video below, the robot arm moves in a fixed manner. We mark 2 positions; One to check mainly for errors along the Y-Axis, another position for errors along the X-Axis.

The results show that the position used to check deviations along the Y-Axis got lower over time (the robot arm was moving for 5 minutes in total), while the error along the X-Axis seemed small. Since the error is in the same direction as the earth's gravitational pull, this might indicate that there indeed were some missed steps. But one could also argue that the precision is within margins considering the gears backlash is about 2.5°. It also seemed like the error was converging to some certain amount.

More time had to be invested to pin down the cause/causes of the error seen in this video. Since it is moving fairly accurate I call it a day. The next project's waiting!

Buy the 12V 28BYJ-48 stepper motors used in this project on Amazon (Affiliated link):

Read more here:

Комментарии

0:02:10

0:02:10

0:00:46

0:00:46

0:01:15

0:01:15

0:00:28

0:00:28

0:01:58

0:01:58

0:00:44

0:00:44

0:01:36

0:01:36

0:00:38

0:00:38

1:00:30

1:00:30

0:00:25

0:00:25

0:00:58

0:00:58

0:06:15

0:06:15

0:01:23

0:01:23

0:01:49

0:01:49

0:56:38

0:56:38

0:04:15

0:04:15

0:01:34

0:01:34

0:00:51

0:00:51

0:01:40

0:01:40

0:00:20

0:00:20

0:00:15

0:00:15

0:04:23

0:04:23

0:01:38

0:01:38

0:00:21

0:00:21