filmov

tv

Drawing an Involute Spur Gear from Scratch in Fusion 360

Показать описание

In this video I show how to draw a Spur Gear from scratch in Fusion 360. Instead of approximating the involute curve of the gear tooth, we calculate it using a spreadsheet (see the link above) and import the curve to our model for an accurate representation of the gear teeth.

Although I used Fusion 360 for this example, the technique used can be easily translated into any CAD software using this method.

#fusion360 #CAD #maker #spurgear

Drawing an Involute Spur Gear (HD)

Spur Gear Design 2 - Involute of the circle

Drawing an Involute Spur Gear from Scratch in Fusion 360

Involute Gears Explained

How To Draw An Involute Gear Tooth Profile| Machine Drawing | Edusquad

Mechanical Drawing 202 Ep. 2 - Designing An Involute Spur Gear (Part 1)

INVOLUTE SPUR GEAR CONSTRUCTION, formulas and calculation involve, UNWIN'S

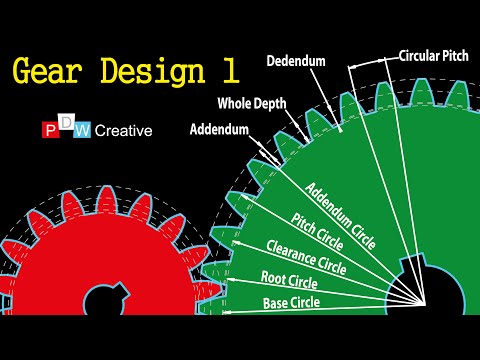

Spur Gear Design 1 - How gears work

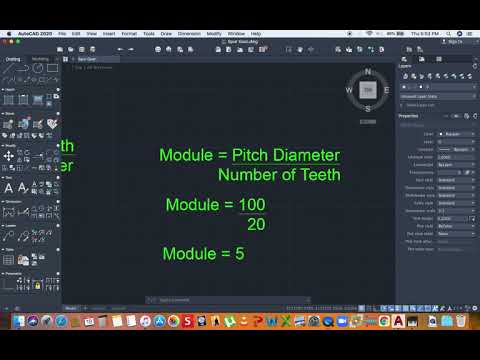

How to create spur gear in AUTOCAD (Approximate)

Drawing Gears with a Compass (simplified method)

solidwork Spur gear using involute profile

Mechanical Drawing 202 Ep 3. Designing An Involute Spur Gear (Part 2)

Design Of Spur Gear with Equation in SolidWorks

Mechanical Drawing 202 Ep. 1 - Introduction To Involute Spur Gears

Creo Parametric - Spur Gear Design | Involute Curve

Understand and Design Involute Spur Gears From Scratch |JOKO ENGINEERING|

involute gear

AutoCAD 2D: Involute Profile of Spur Gear | TechTutorials

Involute Gears

Involute Gears 3: Contact Ratio

Construction of teeth profile Problem - Spur gear Drawing - Involute Profile

How to draw a spur gear involute profile in AutoCAD/GStarCAD/ZwCAD with LitioLAB

Involute Gears 2: Undercut and Profile Shift

Spur Gear Design 3 - Construct, Edit and Animate

Комментарии

0:24:01

0:24:01

0:03:04

0:03:04

0:18:03

0:18:03

0:06:40

0:06:40

0:19:39

0:19:39

0:41:38

0:41:38

0:32:37

0:32:37

0:05:52

0:05:52

0:07:27

0:07:27

0:03:02

0:03:02

0:10:00

0:10:00

0:29:49

0:29:49

0:15:59

0:15:59

0:27:11

0:27:11

0:18:14

0:18:14

0:22:26

0:22:26

0:09:54

0:09:54

0:06:28

0:06:28

0:27:46

0:27:46

0:08:01

0:08:01

0:20:55

0:20:55

0:01:28

0:01:28

0:13:33

0:13:33

0:31:46

0:31:46