filmov

tv

Spur Gear Design 1 - How gears work

Показать описание

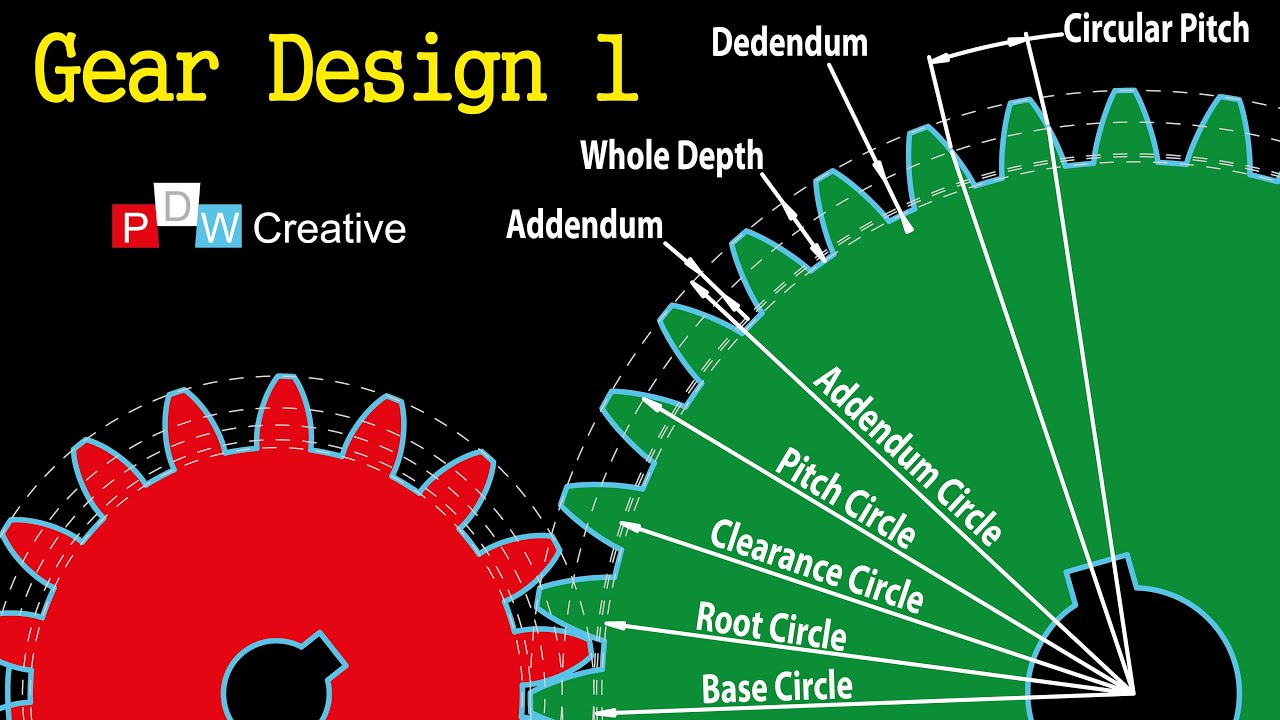

How to design interacting or meshing gears of different diameters, identify which characteristic controls the gear ratio and why the module is important. The relationship between addendum and dedendum in terms of clearance is also discussed.

This video details characteristics of gear design including the top land, face, flank, bottom land, gear tooth profile, pitch circle, circular pitch, dedendum, addendum, whole depth, addendum circle, clearance circle, root circle, base circle, pressure angle, line of action and angle of interaction.

This video details characteristics of gear design including the top land, face, flank, bottom land, gear tooth profile, pitch circle, circular pitch, dedendum, addendum, whole depth, addendum circle, clearance circle, root circle, base circle, pressure angle, line of action and angle of interaction.

Spur Gear Design 1 - How gears work

Rack and Pinion Design 1 - spur gear design in solidworks

Spur Gear Design 2 - Involute of the circle

Design Of Spur Gear with Equation in SolidWorks

Gear Design | Spur Gears

Drawing Gears with a Compass (simplified method)

Gear Types, Design Basics, Applications and More - Basics of Gears

Solidworks tutorial | Design of Spur gear with Solidworks toolbox

MEUS SCX10 SCX10ii Capra LCG Chassis preview

Gear 'Module' Explained in 1 Minute

Spur Gear Design Assignment, Part 1, Assembly and Theory

Spur Gears - Force Components - Gear Force on Shaft - Example 1

SPUR GEAR DESIGN⚙️

solidworks tutorial - how to make spur gear . specially for beginers.

How to design a Reduction Spur Gear Box ( Ratio 1:3) Link in description #355 | Design with ajay |

Normal Diametral Pitch & Module on an Engineering Drawing for Spur & Helical Gears || Course...

Spur Gear Design Procedure based on Wear Condition (Part - 1)

HOW TO DESIGN A SPUR GEAR IN CATIA | CATIA TUTORIAL #1

Designing a Spur Gear in SolidWorks: A Step-by-Step Tutorial

How to create spur gear in AUTOCAD (Approximate)

How to Design and 3D print basic spur gears, and how to attach them to shafts (Gears part 1/7)

Iris design 1 | Spur gear | Catia V5 Assembly

Solidworks tutorial - Spur gear design

MACHINE DESIGN: PAST BOARD EXAM PROBLEMS CHAPTER 16 - GEARS PART 1 (SPUR & HELICAL)

Комментарии

0:05:52

0:05:52

0:24:17

0:24:17

0:03:04

0:03:04

0:15:59

0:15:59

0:08:35

0:08:35

0:03:02

0:03:02

0:15:45

0:15:45

0:13:17

0:13:17

0:02:21

0:02:21

0:01:05

0:01:05

0:08:33

0:08:33

0:03:30

0:03:30

0:49:21

0:49:21

0:03:47

0:03:47

0:00:27

0:00:27

0:01:12

0:01:12

0:09:23

0:09:23

0:07:39

0:07:39

0:19:48

0:19:48

0:07:27

0:07:27

0:36:53

0:36:53

0:39:46

0:39:46

0:11:14

0:11:14

1:01:16

1:01:16