filmov

tv

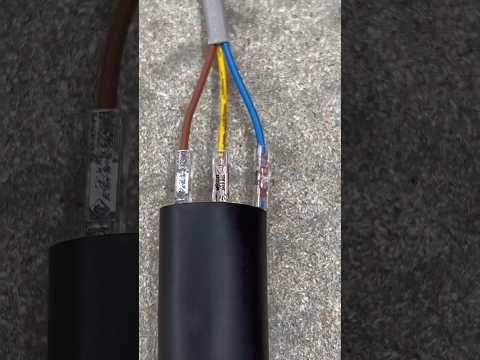

The Ultimate Cable Repair Solution: Wago Inline Connectors

Показать описание

Discover the ultimate solution for repairing damaged cables! This captivating video introduces a game-changing innovation: the Inline Pushwire from the Wago 2273 range. Say goodbye to the hassle of butt or through crimps. But that's not all! We top it off with our beloved adhesive heat-shrink 3M-MDT-A, ensuring this cable join is unbreakable. Don't miss out on this incredible combination of old and new techniques!

We discussed this solution during eFIXX TV - Let us know your opinion

#wago #electricalwork #cables

We discussed this solution during eFIXX TV - Let us know your opinion

#wago #electricalwork #cables

The Ultimate Cable Repair Solution: Wago Inline Connectors

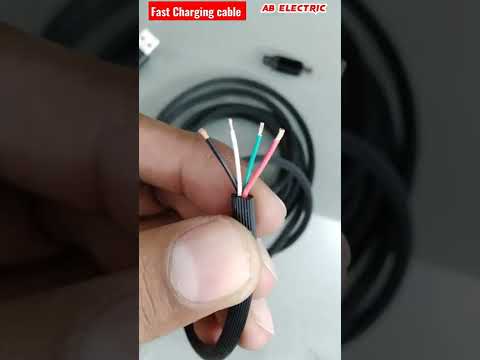

BEST WAY TO FIX AND REPAIR CHARGER CABLE (repair any type of charger cable )

$50 Cable Management Fix

Best way to repair and fix charge cable - fix and repair any type of charger cable

How To Fix A Broken iPhone Charger Cable

How to Protect your Charging & Usb Cable 100% working...

Cable Fix Solder New end on ANY cable

How to Protect your Charging & USB Cable 100% working..2022. Part-2 😮😱

Why Your Quest 2 Battery Won’t Last (And How to Fix It)

how to fix broken mobile charger cable | Lifehacks #shorts #lifehacks #youtubeshorts

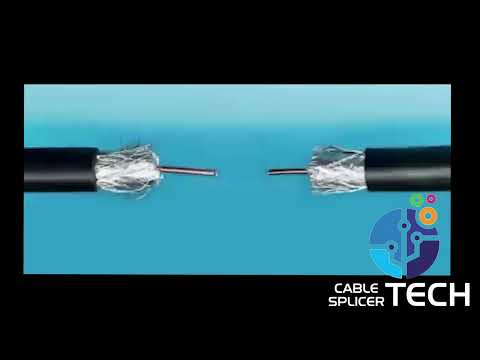

Here Comes The Repairman's Secret Trick! Connect Tv Antenna Cable Correctly & Firmly

Ingenious Method! Fix All Plastic Parts Using Cable Ties

How to repair broken phone charger cable

how fix fast Charging cable

Ultimate Cable Management Hack For Your Setup

Don't Throw Away Broken Charging Cable ! Easy Way To Fix It And Save Your Money

4 Minute Fix for Damaged Power Cord / Plug Replacement

How To Fix A Cut Coaxial Cable-F Connector Repair Tutorial

How to Repair a Broken Ethernet Cable? | VCELINK

FIX FLEX CABLE

HOW TO REPAIR USB CHARGING CABLE | HOW TO FIX IPHONE CABLE | Fix ANY damaged cable with ease.

How to Joint Coaxial Cable without Connectors

Easy way to protect the charger data cable #shorts

Do not throw away the original cable of the phone, but fix it in seconds

Комментарии

0:00:53

0:00:53

0:04:04

0:04:04

0:05:36

0:05:36

0:06:58

0:06:58

0:08:39

0:08:39

0:02:58

0:02:58

0:03:48

0:03:48

0:01:31

0:01:31

0:11:23

0:11:23

0:00:30

0:00:30

0:03:05

0:03:05

0:05:16

0:05:16

0:01:35

0:01:35

0:00:22

0:00:22

0:00:40

0:00:40

0:06:29

0:06:29

0:04:35

0:04:35

0:03:39

0:03:39

0:01:17

0:01:17

0:01:49

0:01:49

0:06:25

0:06:25

0:00:40

0:00:40

0:00:22

0:00:22

0:08:06

0:08:06