filmov

tv

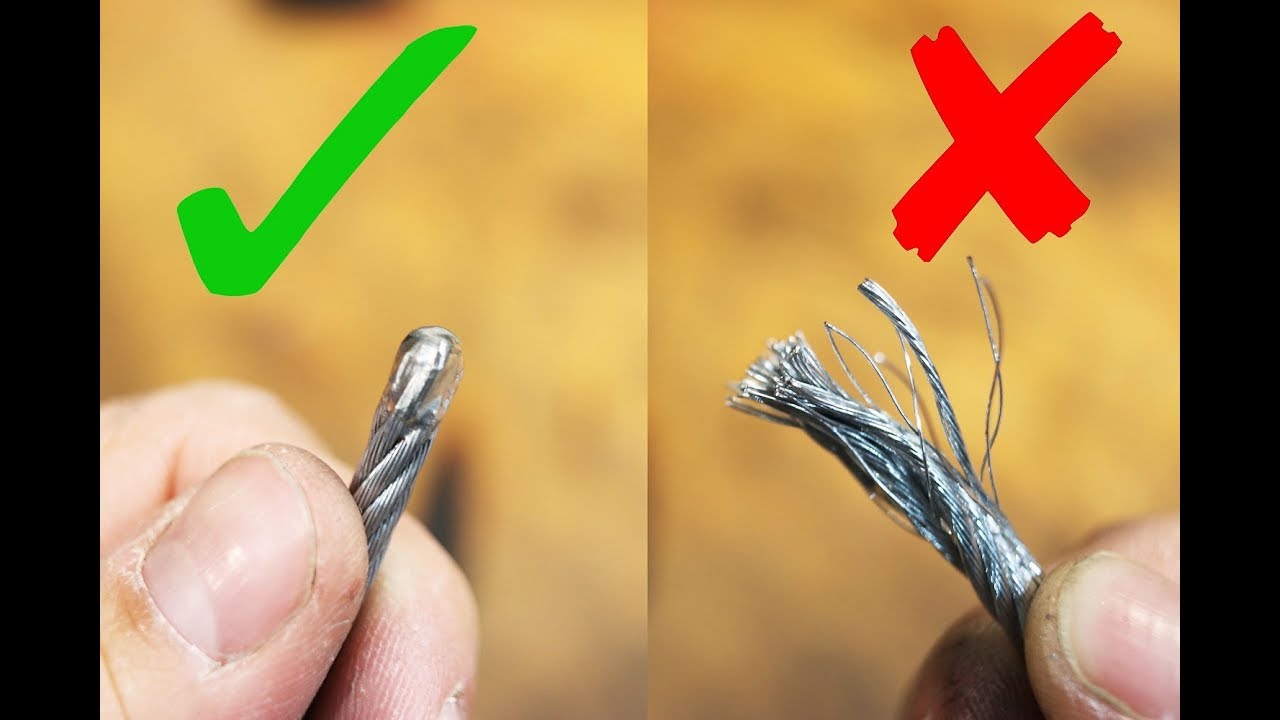

How to keep steel wire cable ends together. No fraying.

Показать описание

The solder I used:

If you heat the wire with a direct flame, it will oxidize and will not bond to the solder. Dipping the wire into molten solder is much more effective. Once this is done your, steel wire cable will not come undone, unravel, or unwind. This solder stop will keep all the wire from fraying.

If you heat the wire with a direct flame, it will oxidize and will not bond to the solder. Dipping the wire into molten solder is much more effective. Once this is done your, steel wire cable will not come undone, unravel, or unwind. This solder stop will keep all the wire from fraying.

How to keep steel wire cable ends together. No fraying.

Must Know Wire Rope Cutting Trick! Stop Frayed Ends! Steel Cable

How To Work With Wire Rope and Wire Rope Clips

Wire Tensioning System Using Nails and Hex Nut - Fence Wire Tensioner

Steel Wire Rope Mini Crimping Tool 1mm 1.5mm 2mm 2.5mm

Tying Off High Tensile Wire

HOW TO CUT STEEL WIRE CABLE WITHOUT SHRED

Clean end loops in steel rope cable

Vertical Trellis for Raised Garden Beds: Step-by-Step Build”

Making Wire Crimps, Swage Balls, Oval Sleeves Video

How to 'cut' wire rope like a pro.

HowTo4: Solder Wire Rope, Ferrous Metals, Stainless Steel

Using Stop Sleeves and Oval Compression Sleeves

How to Tie a Termination Knot High Tensile Smooth Wire

Wire Cable Railing DIY - For Sell @ www.ModernDeckRailings.com

How to Select and Use Swage Sleeves - Installation Guide

How to Select the Right Steel Cable - Buying Guide for Wire Rope and Aircraft Cable

The SIMPLEST Way To Tighten Fence Wire | Strainrite Ratchet Strainer

Installing Wire Rope Cable Thimbles and Choosing the Correct Size

DIY Cable, Clips and Thimbles | Make a Wire Rope with Loops | #shorts

How to clamp grips steel wire Rope Loop 5 tricks.#gone viral video#loop#ideas

▶ How I Cut Wire Rope/Cable

Common Swaging Mistakes

How to Clamp a Wire Rope Ferrule Sleeve Without a Swaging Tool With a Hammer and Punch

Комментарии

0:01:44

0:01:44

0:02:22

0:02:22

0:05:15

0:05:15

0:02:09

0:02:09

0:01:28

0:01:28

0:00:45

0:00:45

0:00:50

0:00:50

0:09:21

0:09:21

0:11:08

0:11:08

0:01:51

0:01:51

0:01:30

0:01:30

0:06:26

0:06:26

0:01:51

0:01:51

0:02:48

0:02:48

0:02:12

0:02:12

0:07:08

0:07:08

0:05:23

0:05:23

0:04:59

0:04:59

0:05:05

0:05:05

0:00:39

0:00:39

0:03:35

0:03:35

0:03:22

0:03:22

0:02:06

0:02:06

0:08:39

0:08:39