filmov

tv

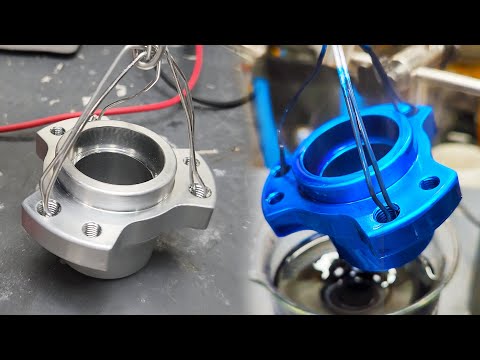

Anodize Your Own Parts any Color with Household Products

Показать описание

DIY - Machining Brilliance - How to Anodize CNC Machined Titanium Parts with Common Household Products… well after Barry fails the first time.

Join this channel to get access to perks:

0:00 What happened??

0:07 DIY Anodizing Titanium

0:48 How to Anodize

2:19 Hydrolysis

2:30 uh oh .. something's wrong

3:08 Copper was the culprit

3:27 How to Anodize the RIGHT way

4:37 Anodized Color fact

5:47 Support us!

Help us fund FREE Education by purchasing tools seen in our videos here:

Create your free CNCEXPERT profile here:

FREE CNC Machining Academy:

FREE Aerospace Academy:

FREE Grinding Academy:

___

___

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #Machinist

Join this channel to get access to perks:

0:00 What happened??

0:07 DIY Anodizing Titanium

0:48 How to Anodize

2:19 Hydrolysis

2:30 uh oh .. something's wrong

3:08 Copper was the culprit

3:27 How to Anodize the RIGHT way

4:37 Anodized Color fact

5:47 Support us!

Help us fund FREE Education by purchasing tools seen in our videos here:

Create your free CNCEXPERT profile here:

FREE CNC Machining Academy:

FREE Aerospace Academy:

FREE Grinding Academy:

___

___

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #Machinist

Anodize Your Own Parts any Color with Household Products

How I Anodize Aluminum Parts at Home

DIY Anodising Motorcycle Parts!

EASILY ANODIZE ALUMINUM At Home | DIY Anodizing Process For Beginners

FULL VERSION. Anodising Colours on Metal with a 9v battery. (Titanium)

This is how I anodize aluminum in 60 seconds!

Annoyingly simple anodising with a 9 volt battery

Black Oxide Coating Parts For Your Own Projects

How To Anodize Titanium! #youtubeshorts #shorts #titanium

Electroplating - Easy DIY Nickel, Copper, Zinc Plating

Anodize Your Own Aluminum Parts!

HOW TO: Anodize Your Aluminum Parts At Home!

Homemade Anodizing Setup

5 WAYS TO RUST PROOF Without Paint!!! CHEAP, FAST & LONG LASTING

Anodizing 3D Printed Titanium

Aluminum Anodizing Keyboard Parts #keyboard #mechanicalkeyboard #anodizing

Anodising titanium

Anodizing 101: Professional Level Finish At a Small Scale!

I Tried to Anodize Car Parts at Home with Unexpected Results! DIY Car Guy Crafts

Anodizing How to Anodize Aluminum!

Anodized and Cerakoted: Know your Finishes!

how to anodise gr5 titanium

Anodizing Aluminum

Electro-Anodizing Titanium Gold!⚡️🎩🇺🇸 #ElectroAnodizing #Anodizing #Anodized #Titanium #Science...

Комментарии

0:06:35

0:06:35

0:02:21

0:02:21

0:06:23

0:06:23

0:10:17

0:10:17

0:02:11

0:02:11

0:01:00

0:01:00

0:00:55

0:00:55

0:24:03

0:24:03

0:00:54

0:00:54

0:09:38

0:09:38

0:14:42

0:14:42

0:12:27

0:12:27

0:04:17

0:04:17

0:11:18

0:11:18

0:00:11

0:00:11

0:00:16

0:00:16

0:00:24

0:00:24

0:12:31

0:12:31

0:15:27

0:15:27

0:00:11

0:00:11

0:00:56

0:00:56

0:00:15

0:00:15

0:00:23

0:00:23

0:01:01

0:01:01