filmov

tv

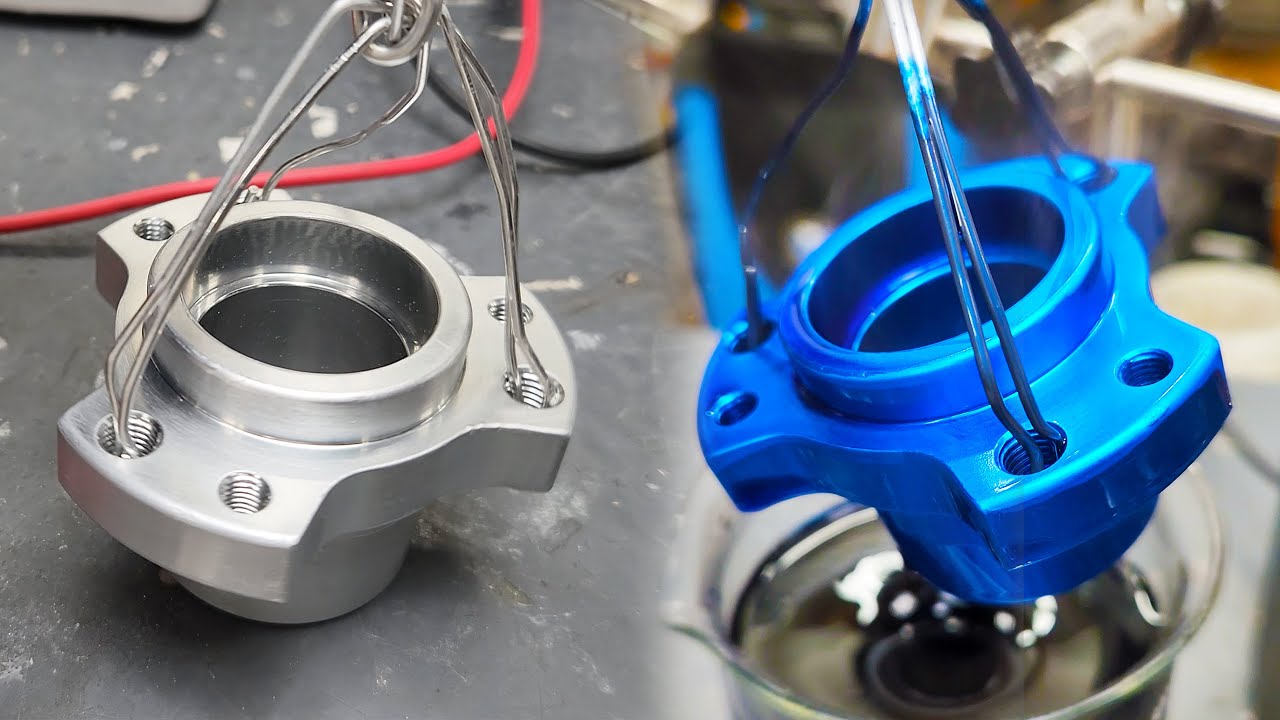

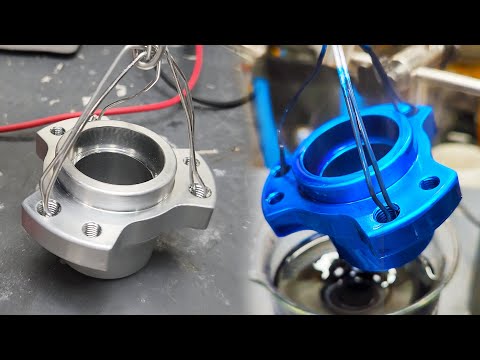

How I Anodize Aluminum Parts at Home

Показать описание

I show You How I Anodize My Aluminum Parts I Make For My Projects.

Anodizing aluminum is a relatively simple process, although it requires some specialized materials and equipment. Here is a step-by-step guide to anodizing aluminum at home:

Clean the aluminum: The first step is to thoroughly clean the aluminum part you wish to anodize. This can be done using soap and water, or a degreaser if there is oil or grease on the surface. You can also use a solvent such as acetone to clean the surface.

Prepare the anodizing solution: To prepare the anodizing solution, you will need to mix a solution of sulfuric acid and water. The concentration of the sulfuric acid will depend on the desired thickness of the anodized layer. A common ratio is 1 part sulfuric acid to 3 parts water. Be sure to add the acid to the water, and not the other way around, to avoid splashing.

Set up the anodizing bath: The anodizing bath should be set up in a plastic or glass container, as the acid can corrode metal containers. The part to be anodized should be suspended in the bath using a hanger or wire.

Connect the power supply: A power supply is needed to create an electric current that will cause the anodizing process to occur. Connect the positive lead of the power supply to the aluminum part, and the negative lead to a piece of aluminum foil or another conductive material in the bath.

Anodize the aluminum: Once the part is suspended in the anodizing bath and the power supply is connected, turn on the power supply and let the part anodize for the desired length of time. The longer the part is left in the bath, the thicker the anodized layer will be. Typically, anodizing times range from 30 minutes to 2 hours.

Rinse the part: After the part has anodized for the desired length of time, remove it from the bath and rinse it thoroughly with water to remove any remaining acid. Be sure to wear gloves and eye protection during this step.

Color Part If Desired: While the anodizing process is going on, heat your dyes. For most colors, 140° F works best for most colors, but some work better at cooler temperatures. You’ll have to experiment with your brands and colors.

Prepare one tank of distilled water and another with your acid neutralizer.

Seal the anodized layer: The anodized layer can be sealed using a variety of methods, such as boiling the part in water or using a commercial sealer. This step helps to improve the corrosion resistance of the part.

Dry the part: Once the anodized layer has been sealed, the part should be allowed to dry completely before use.

That's it! With these steps, you should be able to successfully anodize aluminum at home. However, it's important to note that anodizing involves working with hazardous chemicals and high voltages, so be sure to take appropriate safety precautions and wear protective gear.

Anodizing aluminum is a relatively simple process, although it requires some specialized materials and equipment. Here is a step-by-step guide to anodizing aluminum at home:

Clean the aluminum: The first step is to thoroughly clean the aluminum part you wish to anodize. This can be done using soap and water, or a degreaser if there is oil or grease on the surface. You can also use a solvent such as acetone to clean the surface.

Prepare the anodizing solution: To prepare the anodizing solution, you will need to mix a solution of sulfuric acid and water. The concentration of the sulfuric acid will depend on the desired thickness of the anodized layer. A common ratio is 1 part sulfuric acid to 3 parts water. Be sure to add the acid to the water, and not the other way around, to avoid splashing.

Set up the anodizing bath: The anodizing bath should be set up in a plastic or glass container, as the acid can corrode metal containers. The part to be anodized should be suspended in the bath using a hanger or wire.

Connect the power supply: A power supply is needed to create an electric current that will cause the anodizing process to occur. Connect the positive lead of the power supply to the aluminum part, and the negative lead to a piece of aluminum foil or another conductive material in the bath.

Anodize the aluminum: Once the part is suspended in the anodizing bath and the power supply is connected, turn on the power supply and let the part anodize for the desired length of time. The longer the part is left in the bath, the thicker the anodized layer will be. Typically, anodizing times range from 30 minutes to 2 hours.

Rinse the part: After the part has anodized for the desired length of time, remove it from the bath and rinse it thoroughly with water to remove any remaining acid. Be sure to wear gloves and eye protection during this step.

Color Part If Desired: While the anodizing process is going on, heat your dyes. For most colors, 140° F works best for most colors, but some work better at cooler temperatures. You’ll have to experiment with your brands and colors.

Prepare one tank of distilled water and another with your acid neutralizer.

Seal the anodized layer: The anodized layer can be sealed using a variety of methods, such as boiling the part in water or using a commercial sealer. This step helps to improve the corrosion resistance of the part.

Dry the part: Once the anodized layer has been sealed, the part should be allowed to dry completely before use.

That's it! With these steps, you should be able to successfully anodize aluminum at home. However, it's important to note that anodizing involves working with hazardous chemicals and high voltages, so be sure to take appropriate safety precautions and wear protective gear.

Комментарии

0:02:21

0:02:21

0:10:17

0:10:17

0:06:23

0:06:23

0:15:50

0:15:50

0:01:00

0:01:00

0:06:35

0:06:35

0:01:00

0:01:00

0:14:56

0:14:56

0:12:46

0:12:46

0:33:03

0:33:03

0:03:24

0:03:24

0:12:31

0:12:31

0:00:21

0:00:21

0:07:53

0:07:53

0:08:15

0:08:15

0:06:45

0:06:45

0:37:00

0:37:00

0:01:48

0:01:48

0:07:23

0:07:23

0:12:11

0:12:11

0:15:27

0:15:27

0:00:14

0:00:14

0:15:10

0:15:10

0:00:58

0:00:58