filmov

tv

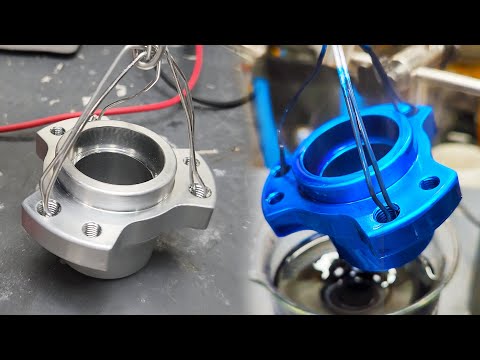

Anodizing 101: Professional Level Finish At a Small Scale!

Показать описание

A total update to my previous anodizing video on how I anodize parts.

Here are the parts lists and calculators

Here are the parts lists and calculators

Anodizing 101: Professional Level Finish At a Small Scale!

How I Anodize Aluminum Parts at Home

What is Aluminium Anodizing and How Does It Work | Anodizing Process Overview

This Is How You Make Your Part Look Incredible | ANODIZING ALUMINIUM | Serious Engineering - Ep22

Electro-Anodizing Titanium Gold!⚡️🎩🇺🇸 #ElectroAnodizing #Anodizing #Anodized #Titanium #Science...

Hardcoat anodizing

EASILY ANODIZE ALUMINUM At Home | DIY Anodizing Process For Beginners

DIY Anodising Motorcycle Parts!

Anodizing Aluminum - How I Anodize and Dye Aluminum Parts

Anodize Like A Pro At Home!

Aluminum Anodizing at Home! No Sulfuric Acid.

DIY Aluminum Anodizing Pt. 2 | Wolf-Haus Industries

Anodized black aluminum plate, interested friends please contact me.+8617852365536

FULL VERSION. Anodising Colours on Metal with a 9v battery. (Titanium)

Removing Anodizing & Polishing Aluminum BMX Hub! (Mirror Finish)

Ni-305 Bright Nickel Electroplating Process for Automobile Parts

How do we anodize handles in our custom shop?

An aluminum spacer formed after several processes:CNC machining,black anodizing,and laser engraving.

DIY Aluminum Anodizing Pt. 1 | Wolf-Haus Industries

How to Anodize Aluminum at Home

TIP For a PROFESSIONAL Wheel Clean INVEST in EZ Detail and Turtlewax Wheel Woolie Brushes #shorts

HOW TO: Anodize Your Aluminum Parts At Home!

HOW TO MAKE THE BEST CAR DESIGN IN ROCKET LEAGUE

Kizer Beglieter with Custom Ano by me #knife #anodizing #titanium #knifecommunity

Комментарии

0:12:31

0:12:31

0:02:21

0:02:21

0:04:37

0:04:37

0:10:32

0:10:32

0:01:01

0:01:01

0:03:50

0:03:50

0:10:17

0:10:17

0:06:23

0:06:23

0:15:50

0:15:50

0:13:08

0:13:08

0:18:14

0:18:14

0:09:20

0:09:20

0:00:24

0:00:24

0:02:11

0:02:11

0:16:08

0:16:08

0:00:15

0:00:15

0:02:15

0:02:15

0:00:39

0:00:39

0:05:45

0:05:45

0:33:52

0:33:52

0:00:30

0:00:30

0:12:27

0:12:27

0:00:24

0:00:24

0:00:37

0:00:37