filmov

tv

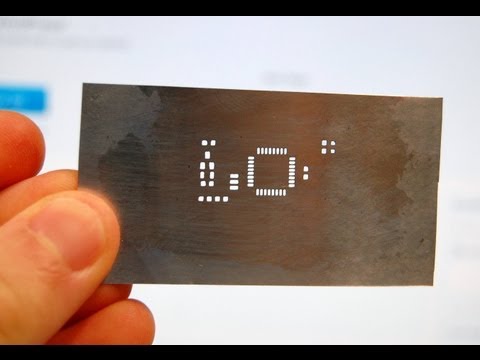

EEVblog #415 - SMD Stencil Reflow Soldering Tutorial

Показать описание

Dave shows you how easy it is to do surface mount SMD reflow soldering with a solder paste stencil and a hot air gun:

Hints and tips for quick and easy component placement, solder paste application, and reflow soldering using cheap easy to get tools.

EEVblog Main Web Site:

EEVblog Amazon Store:

Donations:

Projects:

Electronics Info Wiki:

Hints and tips for quick and easy component placement, solder paste application, and reflow soldering using cheap easy to get tools.

EEVblog Main Web Site:

EEVblog Amazon Store:

Donations:

Projects:

Electronics Info Wiki:

EEVblog #415 - SMD Stencil Reflow Soldering Tutorial

EEVblog #415 SMD Stencil Reflow Soldering Tutorial YouTube

EEVblog #434 - SMD Thermal Pad & Drag Soldering Tutorial

eevBLAB #58 - Engineers Are Underappreciated

EEVblog #239 - PCB Design For Manufacture Part 2

EEVblog #186 - Soldering Tutorial Part 3 - Surface Mount

Small SMD soldering with hot air rework station, solder paste and a stencil to make it easy

Hot air soldering with stencil and solder paste

EEVblog #558 - Beta Layout DIY SMD Thermal Reflow Oven

EEVblog #437 - Removing SMD Parts with ChipQuik

EEVblog #562 - More SMD Oven Reflow

EEVblog #180 - Soldering Tutorial Part 1 - Tools

DIY home-made SMT metal stencil - the definitive tutorial

Using a solder paste stencil (2021)

Cutting SMD stencils

EEVblog #578 - Proprietary Connector Rant - Panasonic LF1

EEVblog #127 - PCB Design For Manufacture Tutorial - Part 1

Yulika RayVio(4)

Solder SMD using SMD/SMT Stencil!

My New Youtube Channel BANNED!

EEVblog #561 - Mailbag

EEVblog #399 - GoPro Hero 2 Teardown

EEVblog #446 - Dumpster Diving Samsung Plasma TV

KiCad PCB Assembly #1: applying solder paste using a stencil - Embedded System Consultant Explains

Комментарии

0:31:00

0:31:00

0:31:01

0:31:01

0:18:12

0:18:12

0:03:42

0:03:42

0:56:54

0:56:54

0:39:56

0:39:56

0:02:03

0:02:03

0:03:00

0:03:00

0:55:27

0:55:27

0:20:47

0:20:47

0:23:48

0:23:48

0:27:14

0:27:14

0:05:48

0:05:48

0:14:10

0:14:10

0:20:35

0:20:35

0:03:42

0:03:42

0:50:46

0:50:46

0:00:06

0:00:06

0:03:55

0:03:55

0:07:08

0:07:08

0:34:12

0:34:12

0:26:46

0:26:46

0:34:16

0:34:16

0:22:29

0:22:29