filmov

tv

How To Pour Epoxy Resin Without Air Bubbles, Properly Preparing Substrates

Показать описание

The most common problem when pouring epoxy resin is developing bubbles during the mixing, pouring & curing process. Although bubbles can occur from incorrectly mixing/pouring epoxy, a very large majority of the problems stem from a porous substrate.

Pouring on a porous substrate like wood will almost alway result in bubbles if the wood has not been properly sealed. Most epoxy manufacturers recommend a very thin seal coat so that bubbles can work there way to the surface. With a large initial pour, the ability of air to rise all the way to the surface is greatly reduced.

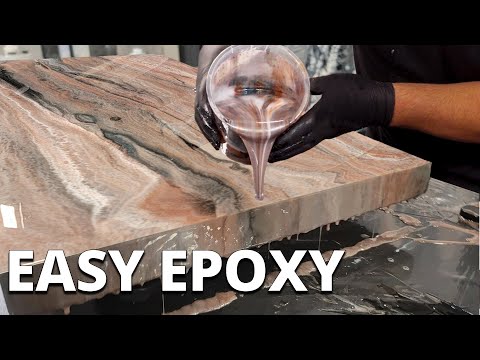

In this video we show multiple different epoxy resin brands poured on three different surfaces, pine, cedar plank and a laminate. The pine is natural with no seal coat or coating. The cedar slab we used a Sand Sealer coating prior to pouring the epoxy. The laminate did not require any prep as this is not a porous surface. As you can see the same epoxy reacts very differently to different surfaces. Needless to say, properly preparing a surface can make the difference between a successful epoxy project and failure.

Our favorite Table Top Epoxy (can also be used as a seal coat):

Комментарии

0:04:26

0:04:26

0:04:56

0:04:56

0:03:15

0:03:15

0:20:32

0:20:32

0:09:25

0:09:25

0:00:15

0:00:15

0:10:02

0:10:02

0:16:35

0:16:35

0:00:56

0:00:56

0:00:59

0:00:59

0:20:58

0:20:58

0:00:54

0:00:54

0:09:33

0:09:33

0:03:53

0:03:53

0:02:50

0:02:50

0:06:08

0:06:08

0:06:27

0:06:27

0:06:52

0:06:52

0:03:47

0:03:47

0:08:16

0:08:16

0:11:40

0:11:40

0:01:00

0:01:00

0:02:42

0:02:42

0:01:01

0:01:01