filmov

tv

This has been a pain in my butt! Learning more about our bandsaw mill…

Показать описание

#bandsawmill #bluecollar #logyard #lumber #familybusiness #woodmizer

Discount code TERI13280

VISIT OUR WEBSITE!

MERCH, MERCH, MERCH! Find it here 👇

Follow us on instagram @lumbercapitallogyard

Discount code TERI13280

VISIT OUR WEBSITE!

MERCH, MERCH, MERCH! Find it here 👇

Follow us on instagram @lumbercapitallogyard

SI joint pain relief🙌 (SI) joint pain has been requested by many of you for me to make a video on....

Common Causes of Kidney and Back Pain

Breakthrough with Healing Chronic Pain | Howard Schubiner | Talks at Google

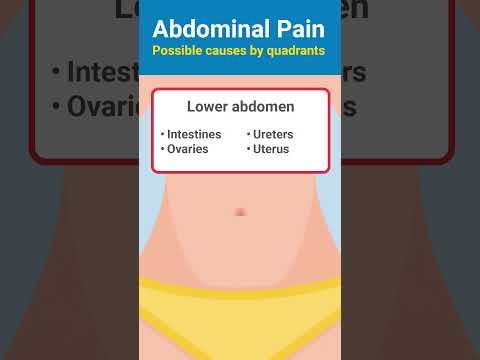

Abdominal pain has many causes, some more serious than others.

Cardiologist explains what Heart Pain feels like

FIX Your Shoulder Pain! | Rotator Cuff Impingement Exercises

Mayo Clinic Minute: What is ulnar wrist pain?

What Is Causing The Pain In My Arm

Live IC/BPS, Pelvic Pain, Pelvic Floor, Hunner's, Widespread Pain Support

Shoulder Pain Relief - Easy Exercise

Hip Pain: 3 Most Common Causes (How To Tell What Is Causing It)

How to Know if Stomach Pain is Serious

How do you know if back pain is muscle or disc?

What Your Hand and Finger Pain Is Telling You | William Seitz, Jr., MD

Best Costochondritis Self-Treatment, No Meds. STOP Alarming Chest Pain!

Neurosurgeon explains: When is low back pain SERIOUS... and you need to take action.

What’s Causing your Foot Pain?

Amazing Solution to Arthritis Pain and Menopause Symptoms - You've Been Waiting For This!

How does your brain respond to pain? - Karen D. Davis

Pain or Pressure Behind the Eye: What It Could Mean | True Eye Experts

Fix Lower Back Pain WIth This #shorts

Why Your Knee Hurts. Knee Pain Types By Location & Description.

This Girl is Able to Feel Other People's Pain | Chicago Med | MD TV

Stop Thumb Pain Now! 3 Simple Fixes

Комментарии

0:00:16

0:00:16

0:05:19

0:05:19

0:53:24

0:53:24

0:00:19

0:00:19

0:03:41

0:03:41

0:11:27

0:11:27

0:01:08

0:01:08

0:01:40

0:01:40

2:49:18

2:49:18

0:00:35

0:00:35

0:06:18

0:06:18

0:02:17

0:02:17

0:02:52

0:02:52

0:35:40

0:35:40

0:13:52

0:13:52

0:04:39

0:04:39

0:01:50

0:01:50

0:12:52

0:12:52

0:04:58

0:04:58

0:01:08

0:01:08

0:00:53

0:00:53

0:04:40

0:04:40

0:07:36

0:07:36

0:05:44

0:05:44