filmov

tv

How to Cut Plexiglass

Показать описание

Segment from "WebTogether"

FOLLOW me on Twitter @JonEakes

FOLLOW me on Twitter @JonEakes

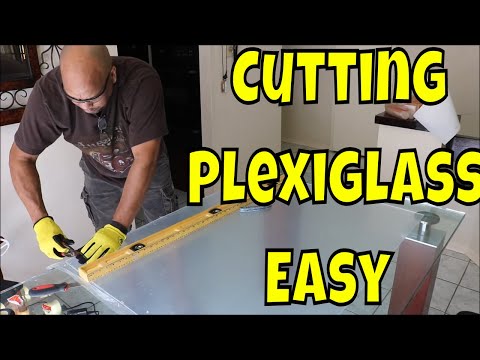

How To Cut Plexiglass The Easy Way

cutting Plexiglas, so easy anyone can do it

How to Easily Cut Plexiglass and Acrylic Sheets

Cutting plexiglass with a jig saw

How to cut plexiglass/acrylic fast and easy with an oscillating tool (multi-tool)

How to Cut Plexiglass Quickly and Easily

How to Cut Plexiglass Without Chipping

How To Cut Plexiglass With A Utility Knife

How To Easily Cut Plexiglass\Using A Tool That May Surprise You!!!

How To Cut Acrylic Sheet By Hand

The best ways to cut acrylic or plexiglass sheets #diy #diyprojects #acrylics #plexiglass

How To Cut Plexiglass With A Jigsaw

Cut Plexiglass and Acrylic Cleanly - Use An Inexpensive Plastic Cutter

How to Hand Cut Plexiglass Easy

How to Cut Plexiglass

How to cut acrylic glass

How to easily cut acrylic sheet

How to Easily Cut Plexiglass

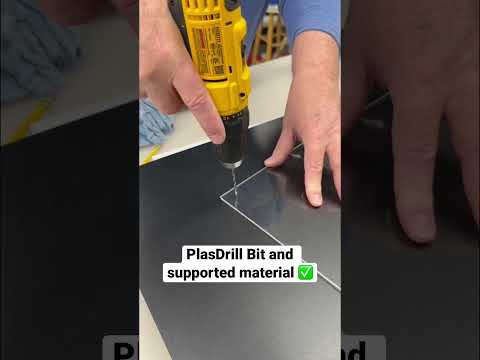

How I Cut & Drill Clear Acrylic (aka Plexiglass)

How to cut plexiglass

Cut Plexiglass, Acrylic, Plastics with Draw Knife Scoring - Cheap, Fast

How to cut acrylic/plexiglass with a jigsaw

What Is The Best Blade For Cutting Plexiglass

How NOT to Drill Acrylic #shorts #fail #diy

Комментарии

0:04:35

0:04:35

0:01:36

0:01:36

0:05:54

0:05:54

0:00:32

0:00:32

0:08:56

0:08:56

0:03:28

0:03:28

0:02:23

0:02:23

0:02:17

0:02:17

0:03:43

0:03:43

0:08:06

0:08:06

0:05:34

0:05:34

0:02:30

0:02:30

0:03:56

0:03:56

0:02:19

0:02:19

0:07:19

0:07:19

0:01:37

0:01:37

0:17:16

0:17:16

0:04:49

0:04:49

0:05:00

0:05:00

0:01:34

0:01:34

0:01:50

0:01:50

0:02:51

0:02:51

0:02:50

0:02:50

0:00:16

0:00:16