filmov

tv

How to adjust sewing machine hook timing

Показать описание

In this video you will learn How to adjust sewing machine hook timing. More information about sewing machine hook timing and how to fiv your sewing machine you find on my website.

The position of the hook tip (timing) in relation to the sewing needle (sewing machine hook timing) is the most important parameter of the quality work of the sewing machine.

The hook tip should be sharp enough, without chipping, otherwise the thread will constantly tear at your sewing machine.

It is necessary to regulate the approach of the hook tip at the moment when the sewing needle, having reached its lowest position, rises upward by 1, 8 mm.

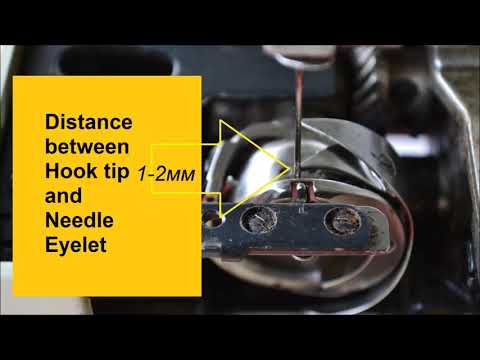

The distance between the hook tip and the upper edge of the needle eye should be within 1 - 2 mm, depending on the type of fabric.

The position of the hook tip (timing) in relation to the sewing needle (sewing machine hook timing) is the most important parameter of the quality work of the sewing machine.

The hook tip should be sharp enough, without chipping, otherwise the thread will constantly tear at your sewing machine.

It is necessary to regulate the approach of the hook tip at the moment when the sewing needle, having reached its lowest position, rises upward by 1, 8 mm.

The distance between the hook tip and the upper edge of the needle eye should be within 1 - 2 mm, depending on the type of fabric.

Sewing Machine Thread Tension - Updated

How to Adjust Tension | Sewing Machine

How to adjust sewing machine hook timing

How to adjust thread tension on some Brother mechanical sewing machines.

How to Set Up a Sewing Machine for Beginners with Angela Wolf

How to Adjust Sewing Machine Tension | Learn to Sew

Sewing Machine Tension Issues SOLVED

How To Adjust Bottom Tension on a Sewing Machine | SEWING WITH STEVE!

The Bernina 990 Sewing Machine Is Officially Here

Thread Tension & Troubleshooting | Sewing Machine Basics

Troubleshooting 3 Common Sewing Machine Problems | Sew Simple Series Lesson #7

How To Adjust Stitch Width and Length on a Brother Sewing Machine

Tension Adjustments for the Sailrite Ultrafeed Sewing Machine

Sewing tension problems upper and lower thread tension explained.

SKIPPED STITCHES ON YOUR SEWING MACHINE | ADJUST HOOK TIMING SETTING | FULL HD VIDEO | EASY TIP

Singer Simple 3337 17 How to Adjust Tension

HOW TO Adjust Top Tension: Tension Assembly & Take Up Spring

How to Fix / Repair the Hook Timing on a Sewing Machine

HOW TO Adjust Bobbin Case Tension

How To: Deal & Understand Tension Problems (Sewing for Beginners)

How To Adjust Top Tension on a Sewing Machine | SEWING WITH STEVE!

Thread Tension Adjustment Explained

How to Thread a Machine | Sewing Machine

BERNINA Jeff How to correct thread tension on your sewing machine fast and easy bobbin tension &...

Комментарии

0:08:51

0:08:51

0:03:35

0:03:35

0:03:15

0:03:15

0:00:42

0:00:42

0:03:54

0:03:54

0:04:43

0:04:43

0:07:11

0:07:11

0:03:51

0:03:51

0:30:23

0:30:23

0:05:35

0:05:35

0:13:38

0:13:38

0:00:48

0:00:48

0:11:28

0:11:28

0:05:38

0:05:38

0:06:28

0:06:28

0:03:40

0:03:40

0:05:25

0:05:25

0:04:35

0:04:35

0:05:41

0:05:41

0:08:09

0:08:09

0:03:47

0:03:47

0:12:08

0:12:08

0:03:39

0:03:39

0:08:22

0:08:22