filmov

tv

Is G10 the best print surface after 5mths?

Показать описание

G10 - The best print surface you've never heard of.

G10 vs Ultrabase Build Plate | My FAVORITE 3D Printing Surface

Is G10 the best print surface after 5mths?

Why I Recommend Using A G10 Sheet With Your 3D Printer

What Is G10?

Best Voron Mod Tested | G10 Build Plate with magnets

JUSTHANGIN' Garolite G10 Build Surface Prep & Installation

Should you own more than one bed surface?

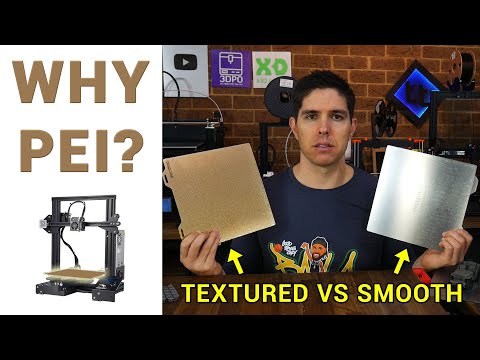

Guide to PEI 3D printer beds: Why and when to use smooth vs textured

Why I love g10 Garolite for my 3d printer bed

G10/FR4 aka Garolite is THE ideal 3d Printer Build Plate material when printing Nylon or PETG!

Garolite G10 G11 printbed surface TEST

Which print surface is the BEST? (for Ender 3 Models)

3d printing on a G10 print bed - leveling issues gone!!! #3d #3dprinting #printing #filament

The BEST Memory Cards! 📷

G10 build plate

Jankiest 3D printing tips that actually work

Stop Using Brims, Do This Instead

Small camera. Big results.

3D print on Fr4 G10 fiberglass sheet #0020 is it better than glass. Matt finish. Garolite

How to make money selling digital designs $$$

This knife was SO hard to deploy

Understand WHY 3D prints WARP - Simple explanation with experiment!

5 3D Printing Tips the ELITES don't want you to know... #3DP101

Комментарии

0:16:44

0:16:44

0:09:52

0:09:52

0:00:28

0:00:28

0:01:07

0:01:07

0:00:35

0:00:35

0:10:12

0:10:12

0:05:31

0:05:31

0:08:42

0:08:42

0:13:30

0:13:30

0:00:14

0:00:14

0:01:46

0:01:46

0:05:44

0:05:44

0:08:34

0:08:34

0:00:21

0:00:21

0:00:45

0:00:45

0:00:04

0:00:04

0:16:20

0:16:20

0:04:33

0:04:33

0:00:15

0:00:15

0:06:05

0:06:05

0:00:48

0:00:48

0:00:16

0:00:16

0:01:38

0:01:38

0:07:26

0:07:26