filmov

tv

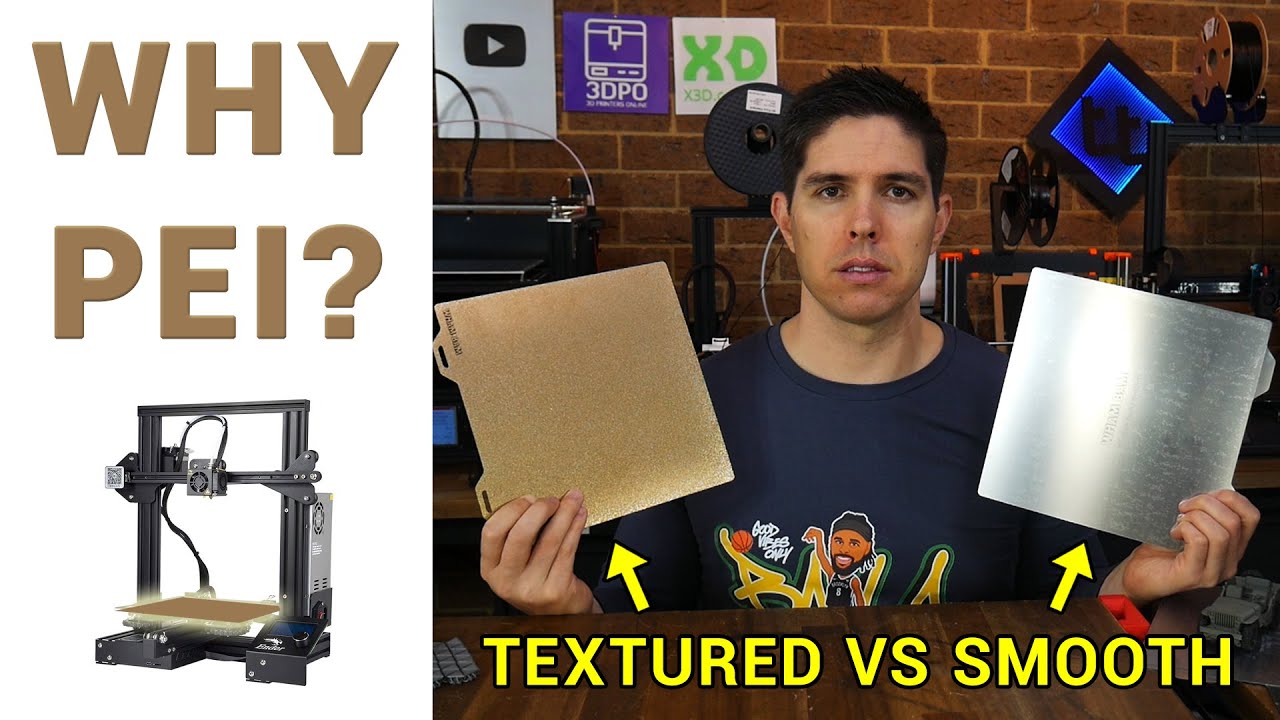

Guide to PEI 3D printer beds: Why and when to use smooth vs textured

Показать описание

By request: What are the advantages and disadvantages of a PEI/PEX 3D printer bed and when is it best to use smooth or textured? This video guide is a summary of my experiences using PEI over the years. I explain why it is my favourite bed material and how I use it for various filaments.

0:00 Introduction

0:39 What is PEI and how is it used with 3D printing?

2:07 Strengths and weaknesses of PEI beds

5:43 Brands I’ve used: variations exist!

6:48 PLA

8:04 TPU

8:34 PETG

10:02 ABS/ASA

10:52 Nylon

11:34 PEEK

12:39 Conclusion

Get Quality Resins from 3D Printers Online. 5% off storewide for Teaching Tech subscribers [Code: tech5]

Take a look around and if you like what you see, please subscribe.

0:00 Introduction

0:39 What is PEI and how is it used with 3D printing?

2:07 Strengths and weaknesses of PEI beds

5:43 Brands I’ve used: variations exist!

6:48 PLA

8:04 TPU

8:34 PETG

10:02 ABS/ASA

10:52 Nylon

11:34 PEEK

12:39 Conclusion

Get Quality Resins from 3D Printers Online. 5% off storewide for Teaching Tech subscribers [Code: tech5]

Take a look around and if you like what you see, please subscribe.

Guide to PEI 3D printer beds: Why and when to use smooth vs textured

Guide: Restoring and maintaining a PEI printbed!

3d Printing PETG For Beginners! Great For Functional Parts

3D Print Not Sticking? 9 Ways to Get Perfect Bed Adhesion

Tips for 3D Printer Bed Adhesion | 5 Tips in 5 Minutes

The 5 Filament Types You Need to Know (And What They're Good For)

3D Print Removal with PEI Sheet

How Good Is TINA2: A $149 3D Printer?! // Complete Beginners Guide

Glass vs. PEI

This is Why PEI beats Glass All Day

Should you get a PEI Build Sheet for your 3D Printer?

Cheap and easy PEI sheet removal with IPA and a scraper

Stop Using Glue Stick for 3D Printer Bed Adhesion!

A Hassle-Free 3D Printer

Removing PETG from PEI/spring steel print bed

How To Use Glue Stick for 3D Printer Bed Adhesion

New Bambu Lab Printer Users - Don't Make These Mistakes

STOP using PLA for 3D printing #shorts

How to Install a PEI Flexible Magnetic Bed on a Ender 3v2 3D Printer (Upgrade)

Things you should know about PETG

Upgrading Your 3D Printer with a PEI Bed: Quick & Easy

The best upgrades for your Bambu Lab 3D printer

Ever wondered how to clean your printers print bed? #shorts

3d print test: Prusa PETG on SMOOTH PEI sheet

Комментарии

0:13:30

0:13:30

0:05:13

0:05:13

0:16:36

0:16:36

0:06:41

0:06:41

0:04:26

0:04:26

0:17:28

0:17:28

0:00:05

0:00:05

0:07:41

0:07:41

0:00:16

0:00:16

0:00:33

0:00:33

0:00:50

0:00:50

0:01:00

0:01:00

0:32:08

0:32:08

0:00:22

0:00:22

0:00:25

0:00:25

0:06:57

0:06:57

0:11:30

0:11:30

0:00:09

0:00:09

0:09:06

0:09:06

0:07:46

0:07:46

0:02:51

0:02:51

0:16:17

0:16:17

0:00:46

0:00:46

0:00:16

0:00:16