filmov

tv

How To Make And Use 3D Printed Router Templates / DIY Router Templates / Woodworking Hacks

Показать описание

In this video I will show you another way to use a 3D printer in your workshop. The primary focus is is how to use 3D printed templates to expand what you can do with your router. Router templates can allow you to make repeatable shapes and designs using a flush trim bit.

Links:

Links:

Make & Do - English In A Minute

How to Use Make and Do in English

Can you use hot glue to make molds? (yes, yes you can)

When & when NOT to use “MAKE” in English

How to Make and Use an Egg Wash | Baking Basics

How to make and use a filing jig for knife blades.

How To Make And Use A Roux

How To Make and Use SIMPLE SYRUP for your CAKES! AND Where To Find My BOTTLE!

Use disposable paper cups to make beautiful creative handmade flowers #diy #parent #handmade

How To Make & Use A Double Boiler | Just The Tip | Steve Konopelski

How to use a French Press to make a Latte | CREMA COFFEE GARAGE

How to make and use a simple trimmer table

How To Make And Use A Water Level

HOW TO MAKE AND USE A WET PALETTE: A Step-By-Step Guide

How To Use AI To Make Faceless Videos In Less Than 5 Minutes

How to Make Whey and Five Ways to Use It

Water level basics – How to make and use one

How to make and use a simple trim router table

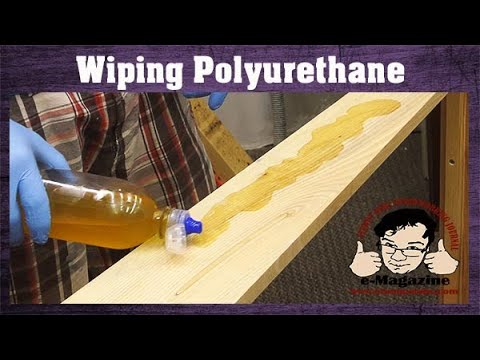

Don't buy wiping polyurethane! (How to make AND use it properly.)

How Do I Make & Use Batter Boards? | DIY Basics

How To Make And Use Simple Syrup | Keep Cakes MOIST!

How to Make and Use an Animatic

How to Make and Use Preserved Lemons

How to Make and Use Fruit Powders | Dehydrating Blueberries | The Purposeful Pantry

Комментарии

0:00:45

0:00:45

0:15:58

0:15:58

0:03:11

0:03:11

0:11:51

0:11:51

0:02:00

0:02:00

0:12:53

0:12:53

0:04:54

0:04:54

0:01:18

0:01:18

0:00:13

0:00:13

0:00:52

0:00:52

0:01:01

0:01:01

0:14:29

0:14:29

0:11:11

0:11:11

0:12:16

0:12:16

0:01:00

0:01:00

0:16:19

0:16:19

0:10:44

0:10:44

0:12:37

0:12:37

0:05:11

0:05:11

0:01:21

0:01:21

0:05:40

0:05:40

0:08:58

0:08:58

0:06:12

0:06:12

0:23:03

0:23:03