filmov

tv

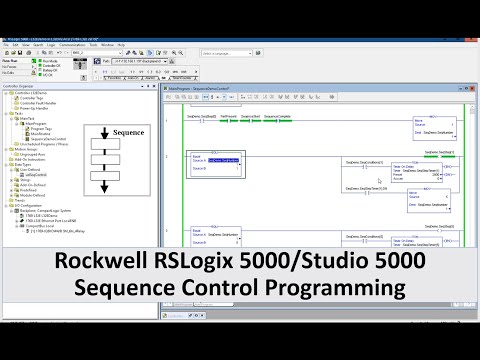

PLC Sequencer Programming - Tutorial on SQI SQO Instructions in RSLogix 5000 Ladder Logic [Part 1]

Показать описание

PLC Sequencer Programming - Tutorial on SQI SQO Instructions in RSLogix 5000 Ladder Logic [Part 1]

Programming a Sequencer in Ladder Logic on a PLC is an advanced skill. It’s a technique which utilizes SQI and SQO instructions in order to create a sequence of events which is based on specific steps & allows the PLC to follow a prescribed sequence of events. Although the squencer isn’t something you’d expect to use on a regular basis, it’s an advanced technique which shines in specific applications.

In this tutorial, we will be going over the use cases of a sequencer, how the SQI and SQO instructions are setup as well as a practical example of a sequencer.

The Sequencer Implementation Strategy

At the core, the sequencer is built from three components: Inputs, Outputs & Step Logic. The inputs are used to determine what’s currently energized and how it enables the sequencer. The outputs are used to identify what needs to be enabled at each step of the sequence. Lastly, the step logic is what will control what’s required to transition from one step to another and which outputs need to be set in a specific step.

A sequencer will work best in applications which are defined by multiple steps which are dependant on each other. As you develop PLC based applications, you will develop an intuition on where to use sequencers. A general rule of thumb is that if you have a process with 3 steps or less, you may implement a simple routine which goes through a series of MOV Instructions instead of a sequencer. As you go beyond this limit, the sequencer will be the preferred method of choice.

PLC Programmers have gotten used to implementing a sequencer through the use of MOV Instructions as mentioned above. Although this technique isn’t advised for larger applications; here’s an example of how this works:

An integer is created & will be used to store the current step of the sequence.

A MOV Instruction is used to change the step of the sequence by writing a specific value into the integer created above.

An EQU Instruction is used to compare the value to a constant & allow certain actions to be carried out accordingly.

Once the actions have been completed, the next step is initiated.

The process is repeated until there aren’t any steps or the sequence is reset.

Find us on social media:

Other Cool Content:

PLC Input Output Mapping / Buffering | IO Addressing Basics in RSLogix Studio 5000 Allen Bradley

PLC HMI Programming Project | Development Tutorial Beginners Ladder Logic Diagram RSLogix | Part 3

RSLogix & Studio 5000 Produced and Consumed Tags | PLC Data Concentrator SCADA, Messaging, EtherNet

HMI Development | FactoryTalk View Studio ME Rotation Animation Tutorial | Pump Fan Motor Program

PLC Vlog#1 - Which PLC Hardware to Buy, When to Invest & What You Should Know before Purchasing PLCs

Relevant Search Terms

plc sequencer tutorial, plc sequence programming, plc sequencer function, plc sequencing, plc sqo, sqo rslogix 500, plc sequential logic, plc sequencing,

Programming a Sequencer in Ladder Logic on a PLC is an advanced skill. It’s a technique which utilizes SQI and SQO instructions in order to create a sequence of events which is based on specific steps & allows the PLC to follow a prescribed sequence of events. Although the squencer isn’t something you’d expect to use on a regular basis, it’s an advanced technique which shines in specific applications.

In this tutorial, we will be going over the use cases of a sequencer, how the SQI and SQO instructions are setup as well as a practical example of a sequencer.

The Sequencer Implementation Strategy

At the core, the sequencer is built from three components: Inputs, Outputs & Step Logic. The inputs are used to determine what’s currently energized and how it enables the sequencer. The outputs are used to identify what needs to be enabled at each step of the sequence. Lastly, the step logic is what will control what’s required to transition from one step to another and which outputs need to be set in a specific step.

A sequencer will work best in applications which are defined by multiple steps which are dependant on each other. As you develop PLC based applications, you will develop an intuition on where to use sequencers. A general rule of thumb is that if you have a process with 3 steps or less, you may implement a simple routine which goes through a series of MOV Instructions instead of a sequencer. As you go beyond this limit, the sequencer will be the preferred method of choice.

PLC Programmers have gotten used to implementing a sequencer through the use of MOV Instructions as mentioned above. Although this technique isn’t advised for larger applications; here’s an example of how this works:

An integer is created & will be used to store the current step of the sequence.

A MOV Instruction is used to change the step of the sequence by writing a specific value into the integer created above.

An EQU Instruction is used to compare the value to a constant & allow certain actions to be carried out accordingly.

Once the actions have been completed, the next step is initiated.

The process is repeated until there aren’t any steps or the sequence is reset.

Find us on social media:

Other Cool Content:

PLC Input Output Mapping / Buffering | IO Addressing Basics in RSLogix Studio 5000 Allen Bradley

PLC HMI Programming Project | Development Tutorial Beginners Ladder Logic Diagram RSLogix | Part 3

RSLogix & Studio 5000 Produced and Consumed Tags | PLC Data Concentrator SCADA, Messaging, EtherNet

HMI Development | FactoryTalk View Studio ME Rotation Animation Tutorial | Pump Fan Motor Program

PLC Vlog#1 - Which PLC Hardware to Buy, When to Invest & What You Should Know before Purchasing PLCs

Relevant Search Terms

plc sequencer tutorial, plc sequence programming, plc sequencer function, plc sequencing, plc sqo, sqo rslogix 500, plc sequential logic, plc sequencing,

Комментарии

0:18:12

0:18:12

0:22:12

0:22:12

0:01:58

0:01:58

0:19:01

0:19:01

0:10:31

0:10:31

0:15:53

0:15:53

0:15:54

0:15:54

2:59:55

2:59:55

0:04:14

0:04:14

0:25:00

0:25:00

0:05:58

0:05:58

0:22:07

0:22:07

0:02:31

0:02:31

0:12:06

0:12:06

0:39:05

0:39:05

0:14:53

0:14:53

0:06:35

0:06:35

0:02:56

0:02:56

0:16:20

0:16:20

0:03:43

0:03:43

0:00:20

0:00:20

0:30:06

0:30:06

0:30:14

0:30:14

0:19:51

0:19:51