filmov

tv

Allen Bradley PLC Sequence Programming Tutorial. MOV Decimal Part 1

Показать описание

In this lesson we are going to show how to program Allen Bradley PLCs to use the EQU Equals instruction and MOV Move instruction to track machine sequence steps. One key advantage to the PLC programming methods in this series is they work with all Allen Bradley PLCs including the Controllogix and Compactlogix with Studio 5000, formerly RsLogix 5000, RsLogix 500 for the SLC 500 and Micrologix PLC, and Connected Components Workbench for the Micro800 PLC. In fact these methods work with most all major PLC manufacturers.

Items used in this video:

The above links make these videos possible. Please use them!

Items used in this video:

The above links make these videos possible. Please use them!

Allen Bradley PLC Programming Sequencer Tutorial. Sequence Control

Allen Bradley PLC Sequence Programming Tutorial. MOV Decimal Part 1

Standard Sequence Programming for Allen Bradley PLC

Allen Bradley PLC - Basic Sequencer Instructions

Allen Bradley PLC Sequence SQI SQO Programming Tutorial Part 9

Allen Bradley PLC Sequence Seal In Programming with Tutorial Part 6

Allen Bradley PLC Sequence MUL Binary Programming Tutorial Part 5

Programming SCARA Robot Sequence Step in Allen Bradley PLC

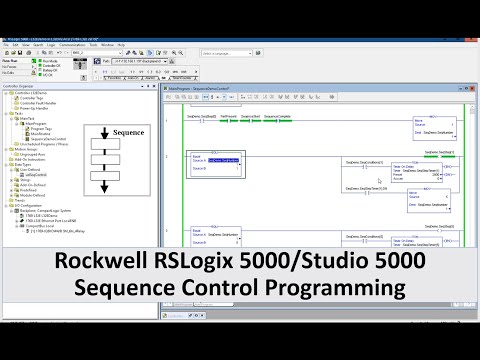

AB05. Rockwell RSLogix 5000 & Studio 5000 Sequence Control Programming

How to Program Allen Bradley PLC Training for Beginners

Sequential Function Chart (SFC) Programming for Beginners

PLC Ladder Logic Basics For Beginners With A Working Conveyor

PLC Sequence Operation Setup to Application | PLC Training | Automation Training

Sequential Function Chart Programming Tutorial

PLC Programming Tutorial | Allen Bradley Training in RSLogix 5000 Ladder Logic Basics for Beginners

Sequencing in Ladder Logic: Step by Step - PLC Programming Cookbook

Allen Bradley PLC Sequence Multiple Counter Programming Part 3

Sequencer SQC ,SQL ,SQO & SQI Instructions for Allen Bradley SLC 500 & MicroLogix 1500 PLCs

Allen Bradley PLC Latch Unlatch Sequence Programming Tutorial Part 7

Allen Bradley PLC Sequence MOV Binary Programming Tutorial Part 4

PLC Programming Sequence of Events

Allen Bradley PLC Sequence Counter Programming Tutorial Part 2

Sequence Output Instruction Part 1

PLC Sequencer Programming - Tutorial on SQI SQO Instructions in RSLogix 5000 Ladder Logic [Part 1]

Комментарии

2:59:55

2:59:55

0:18:12

0:18:12

0:04:13

0:04:13

0:10:31

0:10:31

0:19:01

0:19:01

0:19:09

0:19:09

0:04:56

0:04:56

0:21:14

0:21:14

0:25:00

0:25:00

2:05:49

2:05:49

0:06:40

0:06:40

0:06:35

0:06:35

0:05:58

0:05:58

0:10:52

0:10:52

0:21:43

0:21:43

0:19:28

0:19:28

0:10:34

0:10:34

0:15:54

0:15:54

0:06:06

0:06:06

0:15:25

0:15:25

0:06:38

0:06:38

0:24:23

0:24:23

0:12:06

0:12:06

0:22:12

0:22:12