filmov

tv

TIA Portal: Sequential Programming in LAD/FBD (Available for ALL PLC's)

Показать описание

Here is one way of programming a sequential system using LAD/FBD.

I took the video from my old channel, where the quality was a bit different, but the content still has high quality!

Contents:

- I/O Lists

- System Application

- Functions

- Timer

- Datablocks

- Step Definition

- Step Execution

- Set/Reset/Assign Qualifiers

- Output Assignment

If this video helped you, please consider helping me by joining my "GoFundMe" and donating a small amount to my cause. Link here:

I took the video from my old channel, where the quality was a bit different, but the content still has high quality!

Contents:

- I/O Lists

- System Application

- Functions

- Timer

- Datablocks

- Step Definition

- Step Execution

- Set/Reset/Assign Qualifiers

- Output Assignment

If this video helped you, please consider helping me by joining my "GoFundMe" and donating a small amount to my cause. Link here:

TIA Portal: Sequential Programming in LAD/FBD (Available for ALL PLC's)

TIA Portal: Sequential Programming (S7-GRAPH)

SC02. Siemens TIA Portal Sequence Control Programming

Sequential Programming in Tia PortaL || Traffic Light Exercise

Sequential Function Chart (SFC) Programming for Beginners

How to Create a Sequencer using Shift Registers (SHL) with Siemens TIA Portal!

Sequential Programming with Ladder logic

Siemens TIA Portal & Factory IO (Assembler / Sequential PLC Programming)

SC12. Siemens TIA Portal Graph Sequence Programming and Tips & Tricks

TIA Portal: FC's and FB's When and How to use them and what's the Difference

Know Every Step of the Process: Sequential Function Chart Visualization for SIMATIC PCS 7

TIA Portal: S7-GRAPH Timer (easiest use)

TIA Portal PLC Programming | Function Blocks Timers and Sequence Tutorial Siemens S7-1200 Simulation

SIEMENS - Basic Traffic Light Sequence

TIA Portal: S7-Graph Interlocks, Supervision and Counter

Program Operational Sequences GRAPH

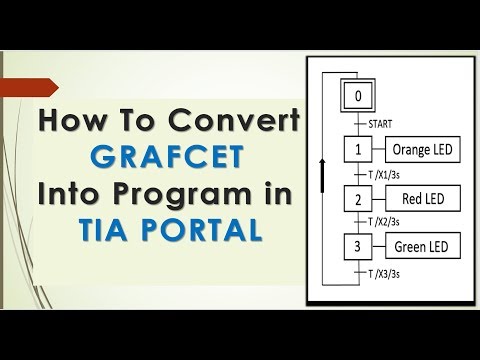

How To Convert GRAFCET To Program in TIA PortaL

Batch mixing and continuous process control with Siemens PLC in TIA Portal

Manipulator Tia Portal sequential programming Factory IO sim

Move Instruction in Siemens PLC Programming - Full Course

Siemens TIA Portal & Factory IO (Creating the PLC Program for Conveyor Sequence, Siemens S7-1200...

TIA Portal: PLC Programming (Beginner Intro)

TIA Portal: Function Block Instances (Single, Multi and Parameter)

SIEMENS TIA Portal programming - Flash the lamp for every 2 seconds using timer

Комментарии

0:30:06

0:30:06

0:32:13

0:32:13

0:23:10

0:23:10

0:14:28

0:14:28

0:06:40

0:06:40

0:23:26

0:23:26

0:15:42

0:15:42

0:11:00

0:11:00

0:38:00

0:38:00

0:26:59

0:26:59

0:03:44

0:03:44

0:08:11

0:08:11

0:18:57

0:18:57

0:14:14

0:14:14

0:21:47

0:21:47

0:11:05

0:11:05

0:11:43

0:11:43

0:06:11

0:06:11

0:00:30

0:00:30

0:11:50

0:11:50

0:45:24

0:45:24

0:13:26

0:13:26

0:18:56

0:18:56

0:23:24

0:23:24