filmov

tv

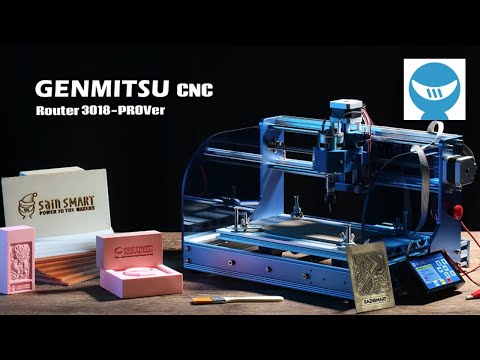

Sainsmart Genmitsu 3018-PROver CNC Router Review and Test(MDF, Acrylic and Aluminum)

Показать описание

Sainsmart Genmitsu 3018 PROVer CNC Router Review and Test #CNC #sainsmart

In today’s video, I’m looking at the Sainsmart Genmitsu 3018 Prover edition. The 3018 Prover is the newest and probably the most refined or most complete iteration of Sainsmart’s Genmitsu series of 3018 CNC routers. And this unit was sent to me by Sainsmart for the purposes of this review.Now, a bit of background about the Genmitsu 3018 routers and 3018 cnc routers in general. These 3018 routers are Arduino powered CNC routers that are built by dozens of Chinese companies and its almost impossible to tell them apart. They were primarily designed and built to be inexpensive desktop cnc routers or mills for engraving wood and plastic, performing milling and slotting operations in plastic and wood, and even milling pcbs or soft metals like aluminum. While several generic manufacturers produce and sell these machines, Sainsmart’s Genmitsu machines have emerged as the quote unquote, branded option. And Sainsmart has been making these machines for quite a few years now and currently sells a few different flavors. The version I am looking at today is the newest version and is also probably the version most suited for folks looking to get into cnc machining as soon as possible, without spending weeks or months tinkering to get the machine working. So let’s take a closer look.

For starters, the 3018-Prover Router machine came semi-assembled and was neatly packed with all the fastners and accessories clearly labeled. In terms of assembly and setup, this machine requires the least amount of assembly of the 3018 machines,but it still takes a few hours to assemble and setup, and does take quite a bit of care and patience to get it working. Once assembled, the machine is fairly compact, measuring in at about 15 inches by 15 inches by 12 inches in height. And just to give you a sense of how compact it is, you can see that it takes up much less than half of my 48 inch workbench. The machine’s frame is made from aluminum and is pretty rigidly built. However the spindle housing or mount is made from plastic, though that doesn’t seem to affect the performance of the spindle. The spindle has a maximum speed of 10000RPM and uses an ⅛ inch ER11 collet which allows you to use bits with a shank diameter of ⅛ inch or approximately 3mm. You can buy ER11 collets with diameters as large as ¼ of inch, but do remember that these larger bits will put more strain on the spindle. The workbed measures 300mm in width by 180mm deep and is also made from aluminum. The bed has slots to accommodate t slot fasteners for clamps. Material can be clamped to the bed using the provided clamps. I cut a few small squares of mdf that I placed under the leveling screws on the clamps, and this prevents the screws from damaging the bed. I also recommend using a piece of wood or thick mdf under your material to act as a spoil board. This is especially important if you’re planning to mill all the way through your material. Unlike other 3018 routers, the Prover comes equipped with limit switches on all three axes, which ensures that the machine's stepper motors don’t burn out, if your g code program tries to push the machine past its physical limits.

In today’s video, I’m looking at the Sainsmart Genmitsu 3018 Prover edition. The 3018 Prover is the newest and probably the most refined or most complete iteration of Sainsmart’s Genmitsu series of 3018 CNC routers. And this unit was sent to me by Sainsmart for the purposes of this review.Now, a bit of background about the Genmitsu 3018 routers and 3018 cnc routers in general. These 3018 routers are Arduino powered CNC routers that are built by dozens of Chinese companies and its almost impossible to tell them apart. They were primarily designed and built to be inexpensive desktop cnc routers or mills for engraving wood and plastic, performing milling and slotting operations in plastic and wood, and even milling pcbs or soft metals like aluminum. While several generic manufacturers produce and sell these machines, Sainsmart’s Genmitsu machines have emerged as the quote unquote, branded option. And Sainsmart has been making these machines for quite a few years now and currently sells a few different flavors. The version I am looking at today is the newest version and is also probably the version most suited for folks looking to get into cnc machining as soon as possible, without spending weeks or months tinkering to get the machine working. So let’s take a closer look.

For starters, the 3018-Prover Router machine came semi-assembled and was neatly packed with all the fastners and accessories clearly labeled. In terms of assembly and setup, this machine requires the least amount of assembly of the 3018 machines,but it still takes a few hours to assemble and setup, and does take quite a bit of care and patience to get it working. Once assembled, the machine is fairly compact, measuring in at about 15 inches by 15 inches by 12 inches in height. And just to give you a sense of how compact it is, you can see that it takes up much less than half of my 48 inch workbench. The machine’s frame is made from aluminum and is pretty rigidly built. However the spindle housing or mount is made from plastic, though that doesn’t seem to affect the performance of the spindle. The spindle has a maximum speed of 10000RPM and uses an ⅛ inch ER11 collet which allows you to use bits with a shank diameter of ⅛ inch or approximately 3mm. You can buy ER11 collets with diameters as large as ¼ of inch, but do remember that these larger bits will put more strain on the spindle. The workbed measures 300mm in width by 180mm deep and is also made from aluminum. The bed has slots to accommodate t slot fasteners for clamps. Material can be clamped to the bed using the provided clamps. I cut a few small squares of mdf that I placed under the leveling screws on the clamps, and this prevents the screws from damaging the bed. I also recommend using a piece of wood or thick mdf under your material to act as a spoil board. This is especially important if you’re planning to mill all the way through your material. Unlike other 3018 routers, the Prover comes equipped with limit switches on all three axes, which ensures that the machine's stepper motors don’t burn out, if your g code program tries to push the machine past its physical limits.

Комментарии

0:13:46

0:13:46

0:11:29

0:11:29

0:05:07

0:05:07

0:22:53

0:22:53

0:16:06

0:16:06

0:00:46

0:00:46

0:00:52

0:00:52

0:15:16

0:15:16

0:09:43

0:09:43

0:16:23

0:16:23

0:00:29

0:00:29

0:08:38

0:08:38

0:00:00

0:00:00

0:31:59

0:31:59

0:11:39

0:11:39

0:36:03

0:36:03

0:07:31

0:07:31

0:10:05

0:10:05

0:08:13

0:08:13

0:06:18

0:06:18

0:14:27

0:14:27

0:00:21

0:00:21

0:11:14

0:11:14

0:01:43

0:01:43