filmov

tv

PROS and CONS of the LT40 Woodmizer

Показать описание

If you want to support us further, you can donate by clicking on this link

Also check out our merch shop!

Also check out our merch shop!

Pros and Cons

Should You Feed Your Dog Organ Meat? Pros and Cons from a Vet!

Pros And Cons of Living in Arizona

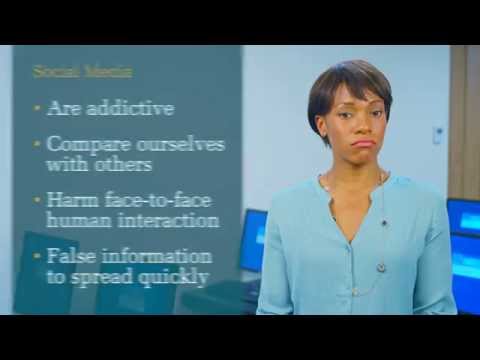

Social Media | Pros and Cons

The Pros and Cons of the ‘Magic’ Drug Psilocybin

The Pros and Cons of Breathing

Virtual Instruments: Pros & Cons

The Pros And Cons Of Dating Smart People. Drew Barth - Full Special

iPhone Pros and Cons: Is It Worth It?#iphone #proses #phone

The Mediterranean Diet: Pros & Cons

The Pros and Cons of Obamacare

Pros and cons Meaning

The Pros & Cons of The Telecaster

The PROS and CONS of Intermittent Fasting

Talking about Pros & Cons in English [Advanced English Conversation Skills]

PROs and CONs of being a DENTAL HYGIENIST

How to Discuss the Pros and Cons of Something | English Grammar with examples

Friends: Rachel Finds Ross' List of her Pros & Cons (Season 2 Clip) | TBS

What Does Caffeine Do to Your Body - the Pros and Cons

Pros and cons of hip replacement surgery

“Pros and Cons of Homesteading”

Social Media Pros and Cons: Community Building to Facebook Addiction

10 Pros & Cons of Home Office

Is Becoming a Pharmacist Still Worth It? REAL Pros and Cons of a Career in Pharmacy

Комментарии

0:00:56

0:00:56

0:09:39

0:09:39

0:04:38

0:04:38

0:02:40

0:02:40

0:03:09

0:03:09

0:03:22

0:03:22

0:00:58

0:00:58

0:39:47

0:39:47

0:01:04

0:01:04

0:05:01

0:05:01

0:11:07

0:11:07

0:00:26

0:00:26

0:01:00

0:01:00

0:11:03

0:11:03

0:10:47

0:10:47

0:07:16

0:07:16

0:33:11

0:33:11

0:03:15

0:03:15

0:06:48

0:06:48

0:04:50

0:04:50

3:20:02

3:20:02

0:02:03

0:02:03

0:01:25

0:01:25

0:14:44

0:14:44