filmov

tv

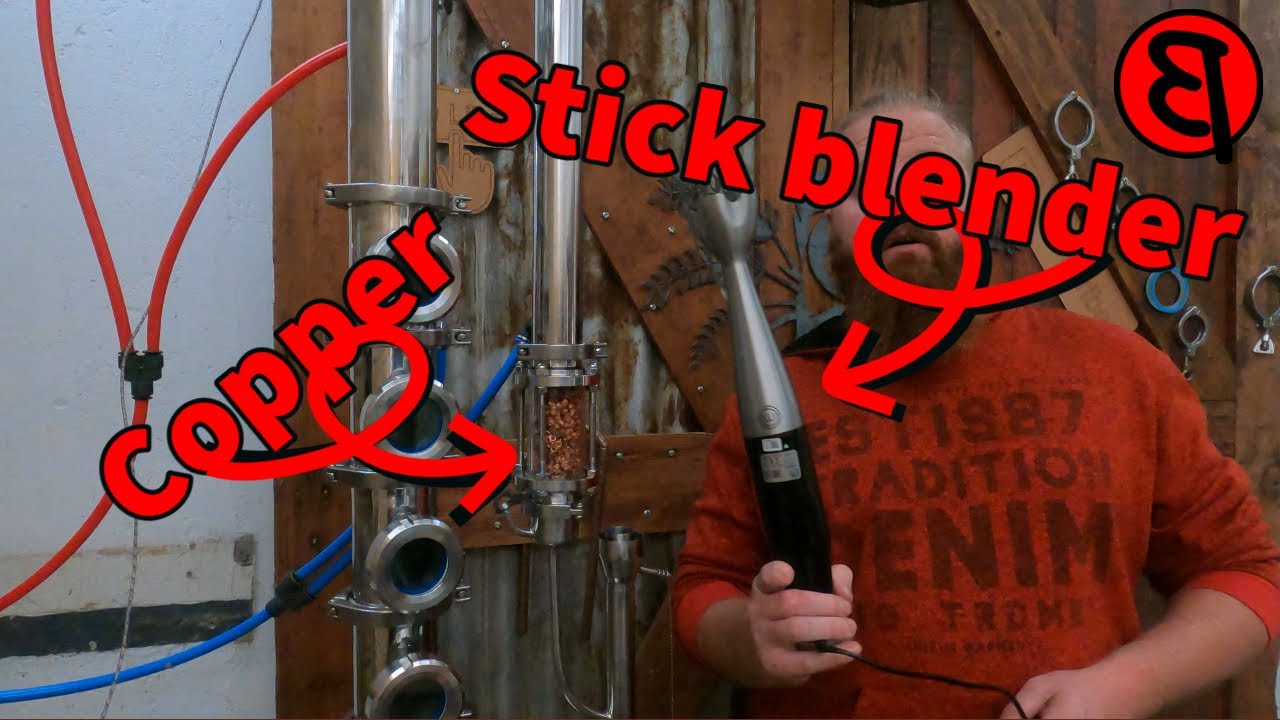

Why I use a blender in my Distillery.

Показать описание

In this video, I will be talking about a stick blender and copper in my column.

@distillerstalk9951 @StillBehindTheBench

#blender #copper

@distillerstalk9951 @StillBehindTheBench

#blender #copper

What is Blender used for?

Why Do Big Video Game Studios Avoid Blender?

WATCH before you buy a blender!!

POV: you trying to learn blender.....

I Learned Blender in a Week

This Is How Much You ACTUALLY Make With Blender

What Can You Do With Blender 3D

Everything Blender can do in one video

Nutrition on the Go with Mbanko Personal Blender

What is Blender Used For

If I Started Blender In 2024, I'd Do This

Stop using Blender!! - Blender Art - #shorts

Learn Blender 3D in 20 Minutes! Blender Tutorial for Absolute Beginners (2023)

8 Blender Hacks You'll Wish You Knew Sooner

3 not so obvious reasons to learn Blender

ABSOLUTE Beginner Basics.. Blender For Noobs

Should I learn Blender 3D or Maya?

3 Ways to Use a Hand Blender | Yummy Ph

7 Blender Addons I recommend to everyone

Types of Lights in Blender

Which Sculpting Technique is Better in Blender?

'When Should You Use a Blender Versus a Food Processor?'

Do You Really Need to Spend $500 on a Blender? | Gear Heads

Using SNAPPING in Blender!

Комментарии

0:02:50

0:02:50

0:06:49

0:06:49

0:00:39

0:00:39

0:01:43

0:01:43

0:09:26

0:09:26

0:08:20

0:08:20

0:10:07

0:10:07

0:12:48

0:12:48

0:00:24

0:00:24

0:11:46

0:11:46

0:10:51

0:10:51

0:00:54

0:00:54

0:18:33

0:18:33

0:03:35

0:03:35

0:00:55

0:00:55

0:08:36

0:08:36

0:08:21

0:08:21

0:01:04

0:01:04

0:00:54

0:00:54

0:00:57

0:00:57

0:04:02

0:04:02

0:00:54

0:00:54

0:08:22

0:08:22

0:00:57

0:00:57