filmov

tv

How to pierce with a plasma cutter #welding #howto

Показать описание

#plasmacutter #piercingcut #howto #thermacut #EX-TRAFIRE #troubleshooting #welddotcom

How to Pierce Your Ear with a Safety Pin

How to Pierce Your Ear

How An Anchor Piercing Works 😮

HOW TO PIERCE YOUR EAR SAFELY - at home

How to Pierce Your Ear #shorts

What's the best method for piercing your ears?

How to practice piercing on a Fake Ear l Piercing tips l Piercing Tutorial l Piercing after care

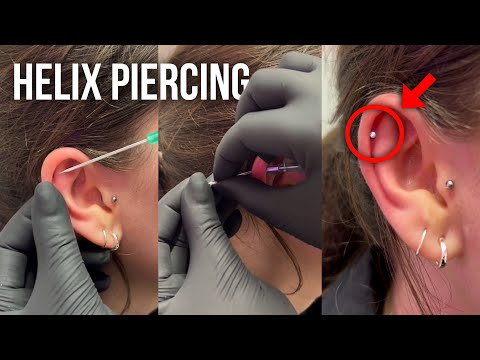

The most popular ear piercing | Helix piercing #piercing #earpiercing #helixpiercing

💎✨DIY Ear Piercing Challenge at Home!

Piercing my own ears with an at home kit. A purse friendlier alternative and relatively pain-free.

Lobe piercing | Quick ear piercing for this guy

Piercing My NOSE with a SEWING Pin

How Ear Gauges Can Tear Your Ears 👂

Watch me pierce my thirds with the Kiseer ear piercing gun.

How To Pierce Your Ear Safely With Safety Pin | Complete Guide

PIERCE MY EAR W ME PT 1 #girl #shorts

How to Pierce Your Own Cartilage

how to pierce your ears at home - super easy

Industrial Piercing

Septum nose piercing for this beauty ⚡️ Don’t try this at home! #septum #nosepiercing

How to Pierce Your Own Nose

How to Pierce Your Septum

Ear 👂 piercings 😱#earpiercings #earrings #hairstyles #viral

DIY Amazon Ear Piercing

Комментарии

0:01:26

0:01:26

0:02:29

0:02:29

0:00:26

0:00:26

0:04:22

0:04:22

0:00:44

0:00:44

0:00:30

0:00:30

0:00:28

0:00:28

0:00:24

0:00:24

0:00:13

0:00:13

0:00:22

0:00:22

0:00:12

0:00:12

0:00:16

0:00:16

0:00:30

0:00:30

0:00:25

0:00:25

0:02:35

0:02:35

0:01:01

0:01:01

0:01:24

0:01:24

0:07:22

0:07:22

0:00:13

0:00:13

0:00:25

0:00:25

0:01:35

0:01:35

0:01:34

0:01:34

0:00:16

0:00:16

0:01:00

0:01:00