filmov

tv

Adam Savage Stumped by This Mystery Lathe Problem

Показать описание

While working on a powered hacksaw build, Adam runs into a problem with his lathe's ability to cut bolt threads, with the machine not cutting the desired threads per inch. It's a bit of a head scratcher as Adam attempts to problem-solve and understand this unexpected behavior before making his fix!

Shot by Adam Savage and edited by Joey Fameli

Music by Jinglepunks

Join this channel to support Tested and get access to perks:

Intro bumper by Abe Dieckman

Thanks for watching!

#adamsavage #onedaybuilds #repair

Shot by Adam Savage and edited by Joey Fameli

Music by Jinglepunks

Join this channel to support Tested and get access to perks:

Intro bumper by Abe Dieckman

Thanks for watching!

#adamsavage #onedaybuilds #repair

Adam Savage Stumped by This Mystery Lathe Problem

Adam Savage Baffled by Obscure Armor-Making Tools!

This Object Should've Been Impossible to Make

Adam Savage's One Day Builds: Giant Nut and Bolt!

The Time Adam Savage Majorly Messed Up With a Client

Dominic Monaghan, Billy Boyd, And Peter Jackson Try To Stump Stephen With LOTR Trivia

Adam Savage Builds Bookshelves for Mrs. Donttrythis!

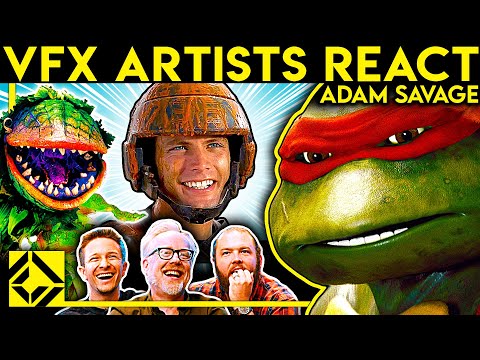

VFX Artists React to Bad & Great CGi 58 (Ft. ADAM SAVAGE)

The First Bag Adam Savage Obsessed Over

On Adam Savage's 'Wild Hyneman' Bits on MythBusters

Adam Savage's Everyday Carry (EDC)

Why Adam Savage Made His Own Hand Clamp

Adam Savage's Custom Ginger Beer Bottle!

Best 'I Told You So' Moments with Jamie

Adam Savage's One Day Builds: Magnetic Lathe Chuck!

VFX Artists STUMPED by New UFO Footage

Adam Savage's One Day Builds: Making a Stable Workbench!

VFX Artists React to Bad & Great CGi 62 (ft. ADAM SAVAGE)

Easter Eggs in Armor?

SCARIEST Myth From MythBusters

Adam Savage Meets Alan Shepard's Mercury Suit!

Adam Savage Finally Fixes His Giant Swiss Army Knife!

The Real Reason Adam Savage Makes Things

What Adam Savage Thinks About AI

Комментарии

0:45:21

0:45:21

0:13:58

0:13:58

0:58:46

0:58:46

0:32:41

0:32:41

0:11:38

0:11:38

0:07:13

0:07:13

0:30:04

0:30:04

0:18:58

0:18:58

0:08:59

0:08:59

0:05:02

0:05:02

0:08:05

0:08:05

0:54:53

0:54:53

0:04:19

0:04:19

0:11:10

0:11:10

0:41:33

0:41:33

0:13:28

0:13:28

0:42:55

0:42:55

0:17:19

0:17:19

0:19:40

0:19:40

0:06:17

0:06:17

0:05:29

0:05:29

0:15:14

0:15:14

0:23:34

0:23:34

0:09:30

0:09:30