filmov

tv

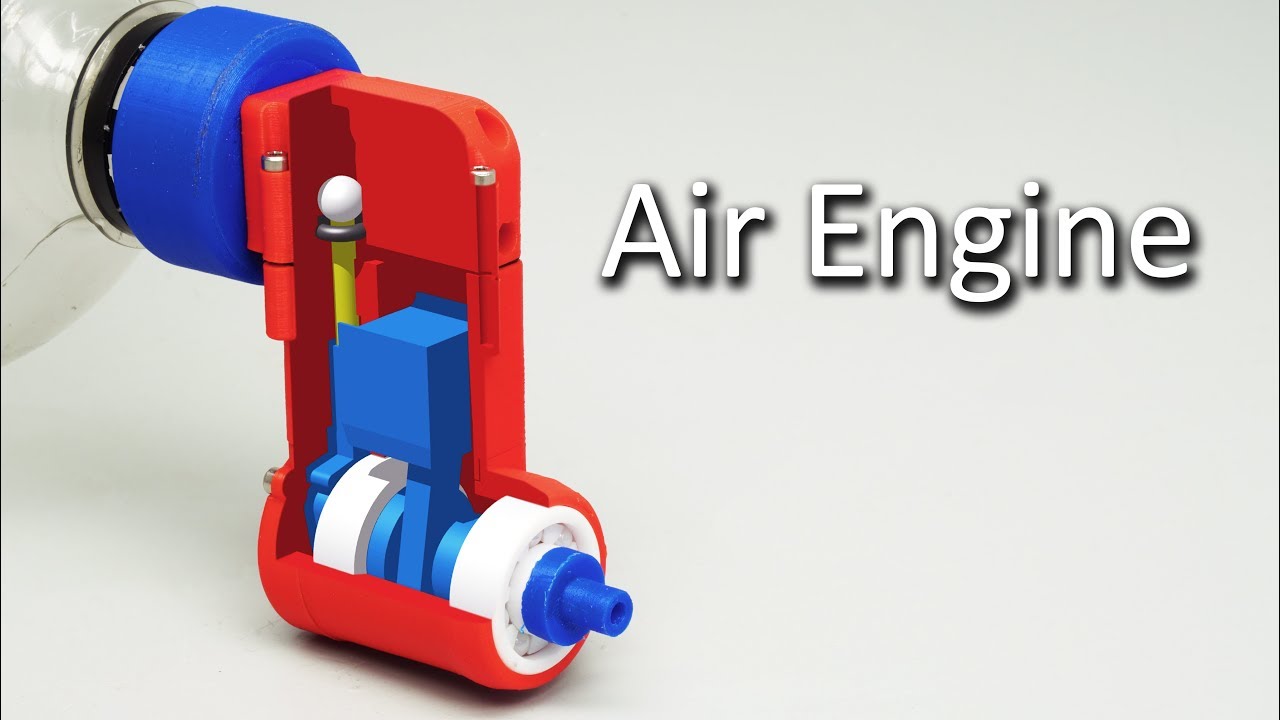

Compressed Air Engine V3

Показать описание

Sponsored by 3D Printz UK:

----------------------------------------------------------------------------------------------------------------------------------------

Huge thanks to the following $5 tier Patrons for supporting me:

Anthony Losego

Robert Kozak

Colin Riordan

Justin Carroll

mcfets

Zohaib Rauf

YCSWYD

Raj Devan

Sergio Di Ventura

Jacques Winter

samyakkapoor

Daniel Barrera

Jim Carroll

Seppo Syrjänen

Calvin Goring

Jared Clark

Callan Schebella

Douglas

Timour Chomilier

Dwayne Myers

Burak Can

Gary H. Baker

Lee Dormon

Nicolas Lagas

Martin Drake

Bruce Carrick

Master of Hexagons

Shane Neubauer

Fiid Williams

Andoni

Lucas Cauthen

Raido Kalbre

paulja

MickWah

Francis Gastellu

Dave Wray

Elias Toft Hansen

Andrew Ebling

Robbie Mackie

Rasmus Backman

James Walkinton

Brandin Link

U.S. Water Rockets

Michelle Powell

Jay Rothwell

Niko Schuster

Mike Close

Michel EDIGHOFFER

KJ

Alper Bahçeliler

Pierre Retief

International Schools Database

Marc Urben

lakshay anand

Jens Schwoon

Anders Wangensteen

Ted Blue Courage

greg cordray

Peter Sripol

Mark Muir

craig rasch

Dave Joubert

Bernard Gauweiler

William Miller

Zoltán Vér

My Other Equipment:

----------------------------------------------------------------------------------------------------------------------------------------

Комментарии

0:11:40

0:11:40

0:00:13

0:00:13

0:14:46

0:14:46

0:20:02

0:20:02

0:00:22

0:00:22

0:08:03

0:08:03

0:00:32

0:00:32

0:14:35

0:14:35

0:09:11

0:09:11

0:10:08

0:10:08

0:09:31

0:09:31

0:14:42

0:14:42

0:13:08

0:13:08

0:14:15

0:14:15

0:12:58

0:12:58

0:00:27

0:00:27

0:00:48

0:00:48

0:00:21

0:00:21

0:00:23

0:00:23

0:00:09

0:00:09

0:00:18

0:00:18

0:00:16

0:00:16

0:00:36

0:00:36

0:10:32

0:10:32