filmov

tv

3 phase motor test

Показать описание

3 phase motor test

how to test 3 phase motor with multimeter

How to test 3-phase motor using MEGGER meter ? Winding resistance and insulation test.

How to test 3-phase motor using MEGGER. Winding resistance and insulation test.

3 Steps - How to check a motor only with a multimeter?

3 PHASE MOTOR TESTING - how too PROPERLY

Phase Sequence/Motor Rotation Tester on 3-Phase Motor [IUEC 394]

How to check your Electrical motor winding - Continuity & Insulation resistance test

BSPHCL TG-III, Full Technical Syllabus Free | 3-Phase Induction Motor Lec-16 | @PrarthanaEducation

Learn Practically How to Check Motor with Insulation Tester @TheElectricalGuy

Ground Testing - Electric Motor - 3 phase motor

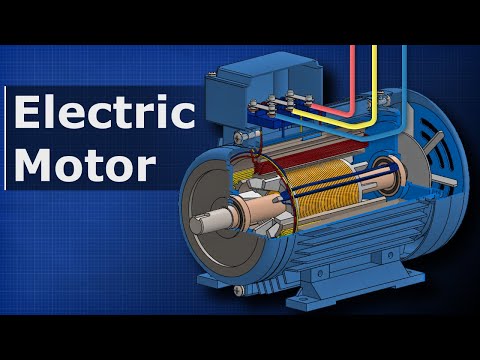

How Electric Motors Work - 3 phase AC induction motors ac motor

How to Meg a Motor with a Megohmeter - Checking Motor Condition

Using the FLUKE 1507 to Identify a bad motor.

How To Troubleshoot 3 Phase Motor With A MultiMeter (3 Phase Motor Test) Winding Resistance Test Ohm

How to test Electrical motors with a multimeter. 3 phase motor testing with multimeter.

3 phase motor testing with multimeter / winding good or failure #tamil #winding #resistance

3 Phase Motor Testing With Multimeter! How to Check 3 Phase Motor! @sn technical

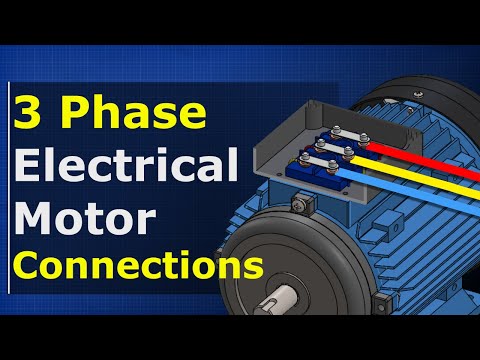

Electrical Motor Connections

How does ABB test electric motors?

Troubleshooting 3 phase motors

How to check a 3 phase motor system

How To Check 3 Phase Power

Checking Windings in a 9 Lead 3 Phase Motor

Комментарии

0:10:58

0:10:58

0:05:59

0:05:59

0:03:38

0:03:38

0:03:50

0:03:50

0:04:37

0:04:37

0:39:04

0:39:04

0:01:46

0:01:46

0:15:43

0:15:43

1:51:10

1:51:10

0:09:35

0:09:35

0:00:43

0:00:43

0:15:34

0:15:34

0:02:44

0:02:44

0:03:18

0:03:18

0:09:26

0:09:26

0:12:41

0:12:41

0:02:37

0:02:37

0:04:08

0:04:08

0:06:16

0:06:16

0:02:57

0:02:57

0:11:45

0:11:45

0:05:06

0:05:06

0:01:17

0:01:17

0:07:55

0:07:55