filmov

tv

How a Machine Shop Checks and Resurfaces a Cylinder Head

Показать описание

We Resurface the Cylinder Head to correct the warpage, test the valves for leaks, check the head for cracks and clean all gasket surfaces. We take off .008' on the head.

How a Machine Shop Checks and Resurfaces a Cylinder Head

Everything you need to know before going to the machine shop | DIY

How do WE clean YOUR engine parts in our machine shop? @JAMSIONLINE

Total Incompetence - Quality is Calling My Parts Wrong… I Checked Everything TWICE… UNBELIEVABLE…...

Measuring Angles in the Machine Shop!

Inside a Full 5-Axis Machine Shop with KCS | Machine Shop Tour

How To Resurface Cylinder Heads

Machining On the mill - Resurfacing (skimming) A-series cylinder head

Blix 8-in-1 RC Megastructures: Build & Operate Your Own Heavy Machine 🚜 | #SiriToyCollections #B...

How to Resurface a Cylinder Head at Home

Machine Shop tools and tricks

Machine Shop Basic Skills -Calibrating A Precision Level

Our Customer Decided On A Fix For The 172 Ford Block!

How-To Machine Chevy 350 Small Block Engine Motorz #64

Do We EVER Grind Valve Seats These Days?

A Day in the Life of A Machinist | Machine Shop Talk Ep. 27

How to Measure FLATNESS Perfectly with Jack Stands

Machine Shop Tour: A Look Inside Rapid Enterprises

DIY CYLINDER BORE CHECK: How to measure OUT OF ROUND, TAPER, and REBORE size - STEP BY STEP GUIDE

Taking our 4.0L XJ Engine to the machine shop

283 Small-block Chevy heads to the machine shop for block and head work

Water Testing Cylinder Heads to Diagnose Compression Issues

Cylinder Head 105 - Valve Job Basics

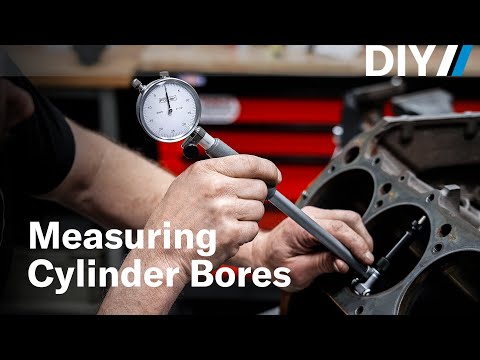

Measuring cylinder bores using a dial bore gauge | DIY

Комментарии

0:15:49

0:15:49

0:06:21

0:06:21

0:17:53

0:17:53

0:04:47

0:04:47

0:18:37

0:18:37

0:06:08

0:06:08

0:04:30

0:04:30

0:14:12

0:14:12

0:00:37

0:00:37

0:03:06

0:03:06

0:15:51

0:15:51

0:09:19

0:09:19

0:05:48

0:05:48

0:23:46

0:23:46

0:08:48

0:08:48

0:13:33

0:13:33

0:08:31

0:08:31

0:02:20

0:02:20

0:10:52

0:10:52

0:11:11

0:11:11

0:13:45

0:13:45

0:04:31

0:04:31

0:14:57

0:14:57

0:09:11

0:09:11