filmov

tv

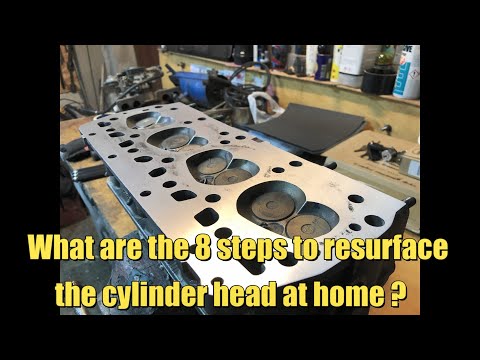

How To Resurface Cylinder Heads

Показать описание

This is not something you do in your garage at home. As you can see in the video, to do this 'properly', you need specialized equipment like the machine you see in this video.

Since not many people get to see this process in action, I decided to make this video while I was at Kalvinator Engines having my engine built, #DarkMatterPikachu.

I hope you enjoy it as much as I enjoyed making this video.

Thanks to Justin Frische for his help in this video.

Camera: Brian Kast

Thanks for watching!

Engine Details

Displacement: 363cid

Compression: 8.9:1

Modified: Edelbrock Performer RPM intake

Related Videos

Social Network Links

Stay Dirty

ETCG

Due to factors beyond the control of EricTheCarGuy, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. EricTheCarGuy assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. EricTheCarGuy recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of EricTheCarGuy, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained in this video is the sole responsibility of the user and not EricTheCarGuy.

Комментарии

0:04:30

0:04:30

0:03:06

0:03:06

0:07:55

0:07:55

0:12:52

0:12:52

0:14:12

0:14:12

0:20:18

0:20:18

0:02:44

0:02:44

0:18:48

0:18:48

0:06:01

0:06:01

0:00:28

0:00:28

0:08:51

0:08:51

0:07:05

0:07:05

0:32:38

0:32:38

0:03:27

0:03:27

0:19:16

0:19:16

0:00:54

0:00:54

0:03:34

0:03:34

0:32:34

0:32:34

0:00:24

0:00:24

0:18:06

0:18:06

0:13:03

0:13:03

0:15:49

0:15:49

0:15:55

0:15:55

0:10:28

0:10:28