filmov

tv

Machine Shop tools and tricks

Показать описание

This video is for apprentices of some one new to machining

there is also some tools that a seasoned tool maker might not know about

We don't all have the advantage of learning on-the-job in a real machine shop, so here are 22 machine shop tips and tricks I've learned that I think are worthwhile! must-have equipment

reference guides

eye loupe

indicator insulator

stopwatch

thread mate

mirror

ray gallant

there is also some tools that a seasoned tool maker might not know about

We don't all have the advantage of learning on-the-job in a real machine shop, so here are 22 machine shop tips and tricks I've learned that I think are worthwhile! must-have equipment

reference guides

eye loupe

indicator insulator

stopwatch

thread mate

mirror

ray gallant

Machine Shop tools and tricks

Tools, Glorious Tools! #4 - Setting Up A Home Machine Shop: Where Do I Start?

Getting Started In Machining - Absolute Beginners Click Here!

14 Machine Shop Tips & Tricks!

I Machined a 50 Million Dollar Part

Some UPGRADES for the Lathe || INHERITANCE MACHINING

Wd40 can trick for the lathe #machinist #shoptips #machining #machineshop

Machinist's Minute: You can double up your studs

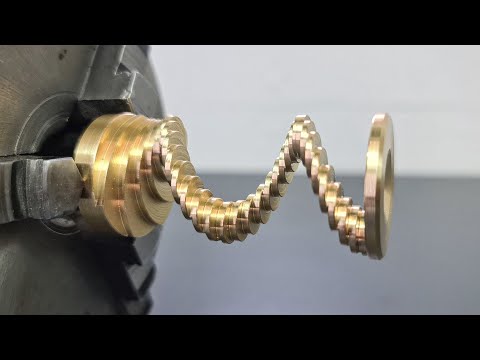

Making a Crazy Part on the Lathe - Manual Machining

Making a PRECISION Machinist Jack || INHERITANCE MACHINING

The OTHER tools nobody tells you about! What does your hobby machine shop need?

Organizing Machine Shop Tools with Aaron: feat. Smokey and Kolby

Top Ten Tools I Use Every Day in the Shop

Why Would You Ever Use CONVENTIONAL Milling??? | Climb vs Conventional

Multi - Functional Woodworking Machine by SN Tools Sliding Table Saw Cutting Machine - 1386#shorts

Machine Shop Training 1 and 2

1975 16mm Machine Shop Educational Film - THE TOOLMAKER'S ART

90% Of Machinists Do This Wrong | This Machining Knowledge is a Game Changer

Home Machine Shop Tool Making - Machining A Finger Plate Clamping Tool - Part 1

Equipment Tour 2023 - Jim's Automotive Machine Shop, Inc.

Edge finding 15 ways for the Milling Machine

Ultimate Machine Shop Toolbox & Organization!

Impressive CNC Lathe Machine Turning

MACHINE SHOP TIPS #118 Making a Form Profile Lathe Tool tubalcain

Комментарии

0:15:51

0:15:51

0:10:31

0:10:31

0:28:21

0:28:21

0:08:02

0:08:02

0:05:44

0:05:44

0:22:20

0:22:20

0:00:25

0:00:25

0:00:58

0:00:58

0:04:15

0:04:15

0:21:02

0:21:02

0:21:57

0:21:57

0:12:39

0:12:39

0:27:40

0:27:40

0:03:37

0:03:37

0:00:30

0:00:30

0:26:18

0:26:18

0:18:39

0:18:39

0:03:56

0:03:56

0:09:23

0:09:23

0:16:31

0:16:31

0:14:24

0:14:24

0:19:34

0:19:34

0:00:10

0:00:10

0:15:42

0:15:42