filmov

tv

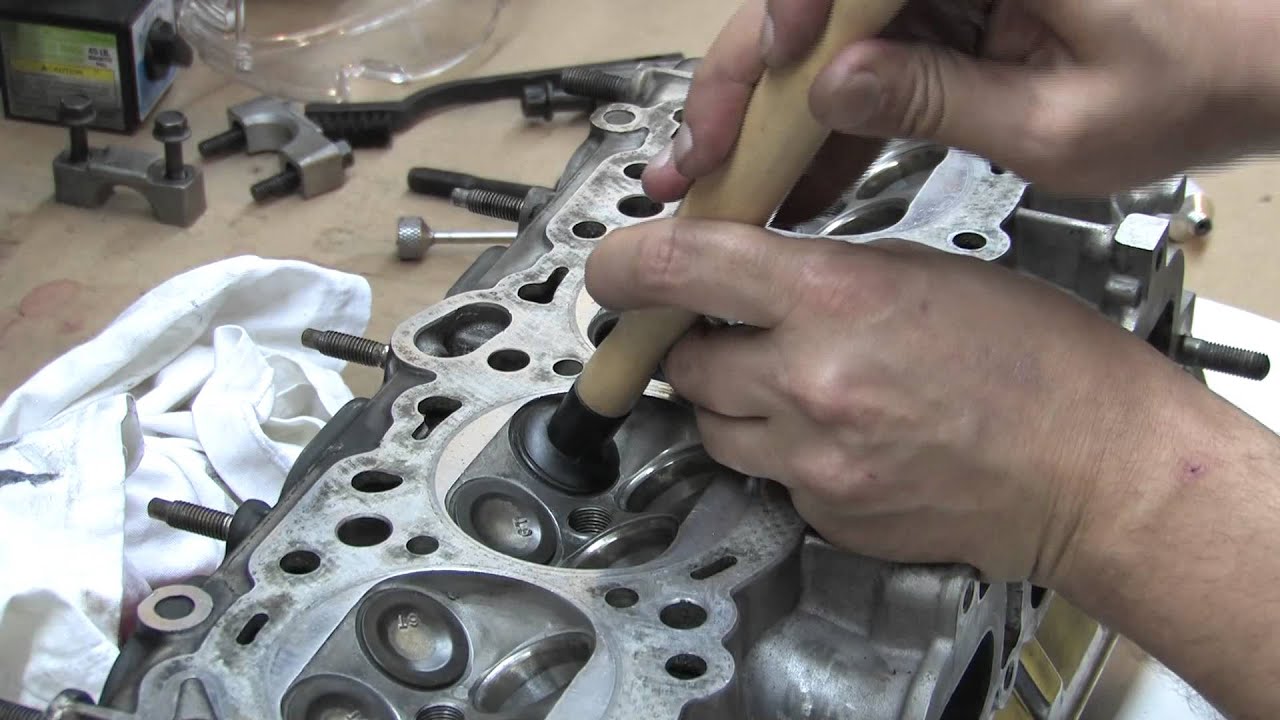

Cylinder Head 105 - Valve Job Basics

Показать описание

Valves not sealing and they're not bent? This is one way to fix that problem.

Once you've completed this work, you can clearly see the size, width, and consistency of the valve mating surface on BOTH the valve, and the seat. Should any distortion appear in the mating surfaces, you will need the help of a machinist to fix this properly.

I outline the cleaning and inspection techniques to help determine whether or not you need to pay a machinist to perform an actual valve job. If you find after performing these steps that your valves don't seat properly, or that your valve seat or valve margin measurements are out of spec, only then would you need a machinist's help.

Here I cover the inspection process start-to-finish. All of these same procedures would be used by your machinist, usually with better equipment... but you can still do the same thing in your garage. These techniques work exactly the same way for just about every non-rotary combustion engine. It takes patience and perseverance, but anyone can do it. Reference your service manual for your engine's specifications and service limits. Everything else that's not in your service manual is in this video.

If you have bent valves, you will discover it quickly once you chuck one up in the drill. You'll see the face of the valve wobble around while it spins. You'll see evidence of this damage on the valve seat. If it's bad, you may see damage on the valve guides in the form of cracks or missing pieces where the valve guides protrude through the head ports. Give all that stuff a good visual inspection.

...and if you doubt yourself, never hesitate to get a second opinion or consult a machine shop. They will have access to expensive tools that you wont find in your average gearhead's home garage. Tools that will give better, faster, more accurate answers than someone could determine with their eyeballs when they don't own those expensive tools.

Lastly: The oxidation found on these valve seats were caused by 110 octane leaded race fuel. Some kinds of race fuel are corrosive to hardened steel valve seats. This head had only about 30,000 miles on it since its last valve job. These techniques will not fix damaged valves without causing a different kind of damage. I'm sorry I had no damaged parts beyond corrosion to show you in this video.

Once you've completed this work, you can clearly see the size, width, and consistency of the valve mating surface on BOTH the valve, and the seat. Should any distortion appear in the mating surfaces, you will need the help of a machinist to fix this properly.

I outline the cleaning and inspection techniques to help determine whether or not you need to pay a machinist to perform an actual valve job. If you find after performing these steps that your valves don't seat properly, or that your valve seat or valve margin measurements are out of spec, only then would you need a machinist's help.

Here I cover the inspection process start-to-finish. All of these same procedures would be used by your machinist, usually with better equipment... but you can still do the same thing in your garage. These techniques work exactly the same way for just about every non-rotary combustion engine. It takes patience and perseverance, but anyone can do it. Reference your service manual for your engine's specifications and service limits. Everything else that's not in your service manual is in this video.

If you have bent valves, you will discover it quickly once you chuck one up in the drill. You'll see the face of the valve wobble around while it spins. You'll see evidence of this damage on the valve seat. If it's bad, you may see damage on the valve guides in the form of cracks or missing pieces where the valve guides protrude through the head ports. Give all that stuff a good visual inspection.

...and if you doubt yourself, never hesitate to get a second opinion or consult a machine shop. They will have access to expensive tools that you wont find in your average gearhead's home garage. Tools that will give better, faster, more accurate answers than someone could determine with their eyeballs when they don't own those expensive tools.

Lastly: The oxidation found on these valve seats were caused by 110 octane leaded race fuel. Some kinds of race fuel are corrosive to hardened steel valve seats. This head had only about 30,000 miles on it since its last valve job. These techniques will not fix damaged valves without causing a different kind of damage. I'm sorry I had no damaged parts beyond corrosion to show you in this video.

Комментарии

0:14:57

0:14:57

0:14:41

0:14:41

0:03:33

0:03:33

0:12:30

0:12:30

0:17:07

0:17:07

0:22:24

0:22:24

0:12:00

0:12:00

0:07:37

0:07:37

0:05:21

0:05:21

0:02:19

0:02:19

0:05:12

0:05:12

0:10:24

0:10:24

0:11:51

0:11:51

0:16:45

0:16:45

0:07:50

0:07:50

0:16:41

0:16:41

0:00:54

0:00:54

0:27:16

0:27:16

0:29:58

0:29:58

0:06:46

0:06:46

0:11:06

0:11:06

0:01:50

0:01:50

0:02:10

0:02:10

0:00:57

0:00:57