filmov

tv

Making bulletproof wood

Показать описание

Back in 2020, I read a paper that claimed that bulletproof wood might be possible. The moment that I saw this, I felt that I had to test it myself and I spent the next 3 years working on it.

References:

CodeBullet: @CodeBullet

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

(when signing up with this link, a portion of your membership directly supports the channel)

Join the community:

You can also find me here:

Making bulletproof wood

Researchers Make Wood Stronger than Steel

Making transparent wood

Making wood as strong as steel!

Hardened Super Wood! - Can It Rival Steel?

Attempting to make transparent wood

What is the science behind bullet proof wood?

Can Glass Cut Wood?

Don't Crush Obsidian

Ballistic test of Super Wood

I Built an Extremely Powerful Slingshot

bullet proof suit 😱

Can you spot the gun?👀 #concealedcarry

Making aerogel

Indestructible Coating?!

Robots testing the Bulletproof #cybertruck

DIY Bullet Proof Interior Wall

Does This 100 Year Old Digging Technique Make Any Sense? #shorts

Cardboard weapon showcase

Use This Trick to Make Your Garage Door Bulletproof!

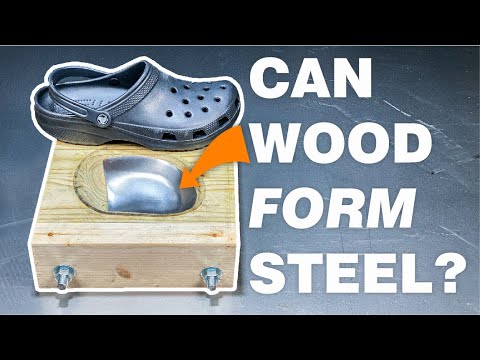

How I made steel toe crocs with wood

FBI made TheBackyardScientist delete his videos

You'll never look as cool... 😎

Let the thighs jiggle, not the gun😜 #phlster #enigma

Комментарии

0:59:38

0:59:38

0:01:35

0:01:35

0:43:55

0:43:55

0:10:54

0:10:54

0:15:10

0:15:10

0:35:49

0:35:49

0:05:28

0:05:28

0:14:06

0:14:06

0:00:57

0:00:57

0:00:24

0:00:24

0:24:24

0:24:24

0:00:16

0:00:16

0:00:19

0:00:19

0:43:56

0:43:56

0:07:09

0:07:09

0:00:34

0:00:34

0:03:40

0:03:40

0:00:35

0:00:35

0:00:15

0:00:15

0:00:55

0:00:55

0:24:15

0:24:15

0:04:48

0:04:48

0:00:20

0:00:20

0:00:17

0:00:17