filmov

tv

MIG Settings for any Thickness

Показать описание

The Everlast welders YouTube channel is the only channel in the industry that is run by the welding community, for the welding community. Every week we will release a new episode taught by the best welders in their respective fields.

#everlastwelders #weldmeanweldgreen #learnwelding

MIG Settings for any Thickness

MIG Welder Settings: MIG Welding Basics for Beginners

Perfect Mig Welder Settings in 3 Easy Steps

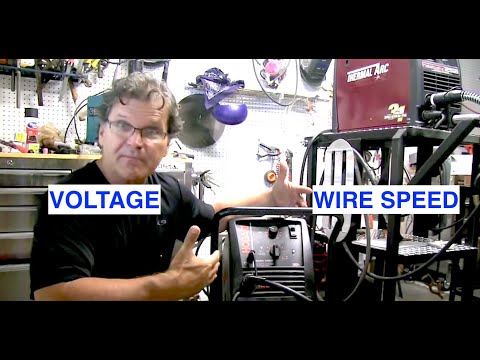

Mig Welding Basics part 3-Setting Voltage and Wire Speed

Setting Wire Speed On A Mig Welder To Match Voltage, Must See For Beginners Learning Welding

MIG Welding Thin Metal to Thick Metal: Here's How

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

How To MIG Weld with Settings

Tips On How To Mig Weld Thin Metal Auto Body Panels #welding #fabrication #howtoweldforbeginners

MIG Welding Basics For Beginners

How NOT TO Weld: Most Common MIG Welding Mistakes

MIG Welding Settings and Techniques Tested - PrimeWeld MIG180

How to Make Consistent MIG Welds

Simple MIG Welding Technique - Flat, Horizontal, Vertical & Overhead | Welding Tips & Tricks...

beginner welding mig # #migwelding #sorts

Short Circuit Mig Fillet Welds and more...

MIG Settings for any Thickness 1080 x 1920

How To Find The Correct MIG Welder Settings For Any Project

How To STACK DIMES With a (MIG Welder) For Beginners🔥🔥🔥

why no welders talk about this Simple OVERHEAD MIG-MAG Welding Technique

PrimeWeld MIG 180 Wire Speed Settings

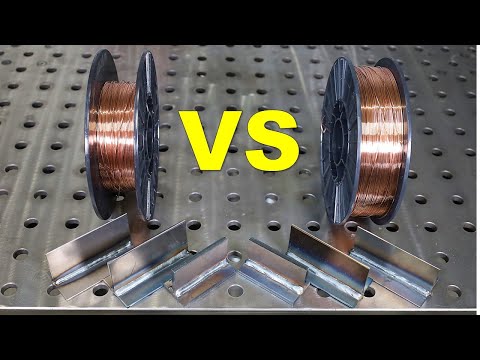

MIG Welding: What Size Wire Should I Use?

(HELP) I Can't See My Mig WELDS (Top 5 Tips)

why no welders talk about this Simple MIG-MAG Welding Technique

Комментарии

0:09:32

0:09:32

0:07:44

0:07:44

0:09:46

0:09:46

0:12:31

0:12:31

0:06:40

0:06:40

0:05:18

0:05:18

0:22:14

0:22:14

0:12:00

0:12:00

0:07:27

0:07:27

0:14:40

0:14:40

0:16:44

0:16:44

0:05:26

0:05:26

0:04:53

0:04:53

0:07:18

0:07:18

0:00:32

0:00:32

0:10:21

0:10:21

0:09:15

0:09:15

0:06:23

0:06:23

0:10:02

0:10:02

0:01:45

0:01:45

0:06:54

0:06:54

0:05:50

0:05:50

0:11:47

0:11:47

0:02:52

0:02:52