filmov

tv

How to use torque wrench for beginners

Показать описание

Click THIS LINK for the worlds EASIEST how to video on using a torque wrench for beginners!

I wanted to show people how to use a torque wrench this video will help the absolute beginners.

I needed a torque wrench for working on my sons truck, I didn't realize how expensive a nice digital torque wrench can be. I ended up like most people forking out 20 bucks on a basic inch-lb wrench and stared haplessly at the numbers on the handle with no clue how it worked.

Then spent the next 30+ minutes getting confused by the instructions and what I found on the internet. There are a ton of review type videos out there and there are as many different types of torque wrenches as there are bolts to turn.

Click on this link to see what else i'm working on!

Please watch: "Why I gave up my C7 Corvette, the trailer"

-~-~~-~~~-~~-~-

-~-~~-~~~-~~-~-

Please watch: "Cinematic Intro 2 in Adobe After Effects Pro CC"

-~-~~-~~~-~~-~-

I wanted to show people how to use a torque wrench this video will help the absolute beginners.

I needed a torque wrench for working on my sons truck, I didn't realize how expensive a nice digital torque wrench can be. I ended up like most people forking out 20 bucks on a basic inch-lb wrench and stared haplessly at the numbers on the handle with no clue how it worked.

Then spent the next 30+ minutes getting confused by the instructions and what I found on the internet. There are a ton of review type videos out there and there are as many different types of torque wrenches as there are bolts to turn.

Click on this link to see what else i'm working on!

Please watch: "Why I gave up my C7 Corvette, the trailer"

-~-~~-~~~-~~-~-

-~-~~-~~~-~~-~-

Please watch: "Cinematic Intro 2 in Adobe After Effects Pro CC"

-~-~~-~~~-~~-~-

How to use a Torque Wrench PROPERLY

How to use a Torque Wrench

How to use a Torque Wrench

How To Use A Torque Wrench For Beginners

How To Use A Torque Wrench For Beginners - 2022

Setting a torque wrench. Easy!

What Is A Torque Wrench & How Do I Use It? | Maintenance Monday

How to use a torque wrench correctly | AUTODOC #shorts

52Pcs Professional Tools, 72 Tooth Dual Direction Bike Torque Wrench Set for MTB, E Bike Review

How To Use A Torque Wrench – GCN's Guide To Tightening Bolts Safely

How to use a Torque Wrench | Tool Basics | The Home Depot

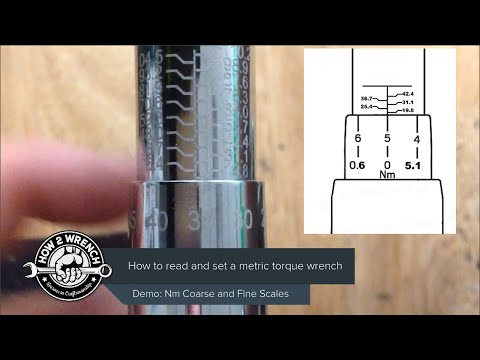

How to use the Newton Meter scale on a torque wrench. Reading Nm and setting the coarse/fine scales.

How to Use a Tagvit Torque Wrench

How to use a Torque Wrench! (the right way)

how to READ and USE a clicker style torque wrench (harbor freight Item#62431)

How to set a Torque Wrench!

how to use a BEAM STYLE torque wrench

Proper Use of Torque Wrenches & Drivers: Click Type

How a torque wrench works

How to Use a Torque Wrench Properly

CALIBRATE YOUR TORQUE WRENCH IN UNDER 5 MINUTES (NO SPECIAL TOOLS REQUIRED!)

How to Use a Torque Wrench

True ZERO Degree Ratchet! #toolsofthetrade #ratchet #zerodegree

How to use torque wrench for beginners

Комментарии

0:08:13

0:08:13

0:01:53

0:01:53

0:02:33

0:02:33

0:04:53

0:04:53

0:08:45

0:08:45

0:06:57

0:06:57

0:07:07

0:07:07

0:00:19

0:00:19

0:04:15

0:04:15

0:05:17

0:05:17

0:01:41

0:01:41

0:03:08

0:03:08

0:00:51

0:00:51

0:00:38

0:00:38

0:02:53

0:02:53

0:10:59

0:10:59

0:01:16

0:01:16

0:04:45

0:04:45

0:05:57

0:05:57

0:13:09

0:13:09

0:08:17

0:08:17

0:01:25

0:01:25

0:00:51

0:00:51

0:08:12

0:08:12