filmov

tv

MUCH STRONGER 3D prints due to LESS COOLING! Testing PLA & PETG

Показать описание

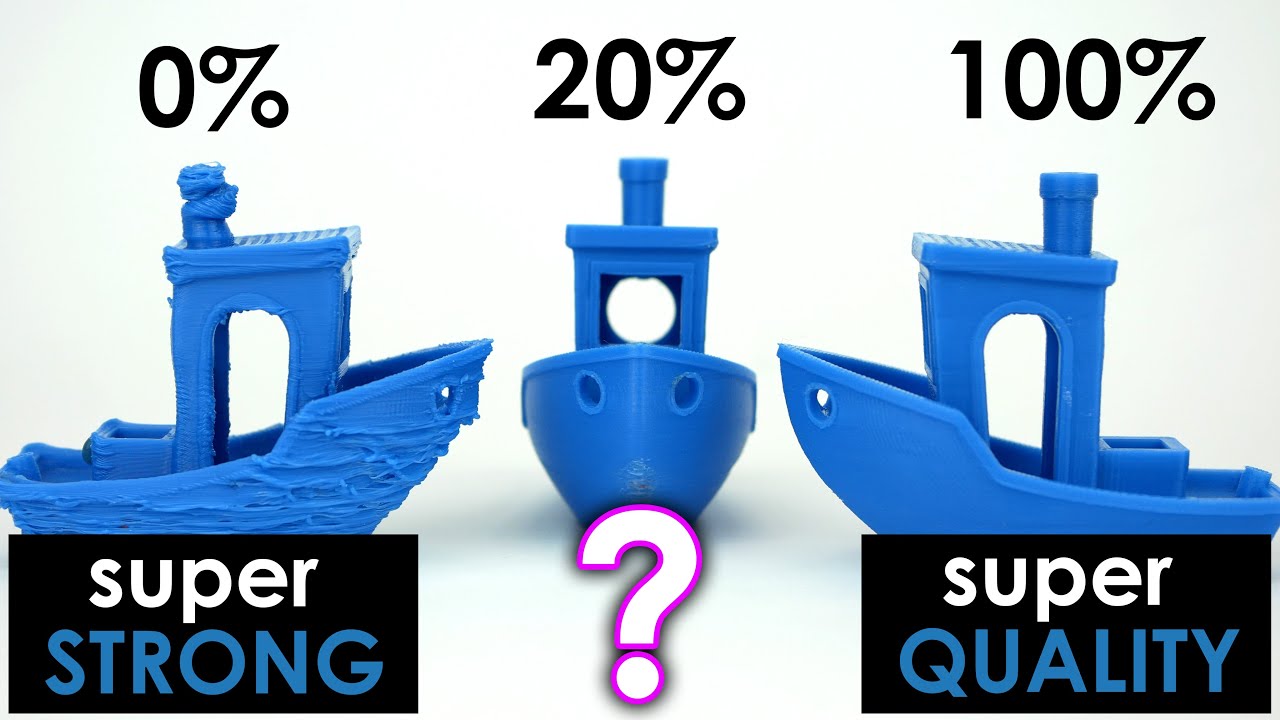

I tested how much the strength or better the layer adhesion of FDM 3D prints is affected by the amount of cooling air we use. By properly adjusting this value we can increase the strength of our parts by more than 50% and make them almost uniformly strong.

I also scanned a couple of 3DBenchys printed at different fan speeds with my AtosCore from GOM to find out how cooling affects the accuracy of 3D prints.

💚 Support me 💚

Join as a YouTube member!

🎙Check out my PODCAST with Tom Sanladerer

TESTED MATERIALS

PRINTED MODELS

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

🏆 Do you want to help me cover my running costs? Send me a dollar or two over PayPal, it helps me a lot!

🌼 Even watching the ads before my videos helps me a lot!

DISCLAIMER: This video was sponsored by Audible.

MUCH STRONGER 3D prints due to LESS COOLING! Testing PLA & PETG

What is the strongest 3D printing material

How much STRONGER is PLA+ really?

The BEST 3D printing material? Comparing PLA, PETG & ASA (ABS) - feat. PRUSAMENT by Josef Prusa

5 must-know 3D printing tips & tricks. (stronger and better looking prints)

Hooked on 3D Printing: What is the Strongest 3D Printer Filament?

Which LAYER HEIGHT gives you the STRONGEST 3D prints?

1857 How To Make Super Strong 3D Printed Parts

Best 3d printing filament for all printers #3dprinting #3dprinted #3dprinter #3dprint #bambulab

Stronger 3D prints at higher temperatures? (strength test!)

Stronger 3D prints with Vapor Smoothing?

STRONGER 3D Prints with GLUE? (and CARBON FIBERS)

Extrusion Width - The magic parameter for strong 3D prints?

Stronger 3D Printed Parts with Electroplating

Why understanding the structure of wood can make stronger 3D prints

The 5 Filament Types You Need to Know (And What They're Good For)

The Best 3D Printed Shoes #shorts

Metal coating 3D printed parts. #3dprinting #science #art

How To Make STRONGER 3D PRINTS

How to connect 3D Printed Parts!

Rethink how you use 3D printer infill!

Don't throw away all your 3D printing filament ends! Do this!

The Ultimate Guide to Perfect 3D Prints

Stop Worrying About Settings and Build Your 3D Printer Right! #Shorts

Комментарии

0:16:11

0:16:11

0:13:40

0:13:40

0:12:29

0:12:29

0:17:13

0:17:13

0:02:44

0:02:44

0:11:24

0:11:24

0:13:33

0:13:33

0:03:58

0:03:58

0:00:42

0:00:42

0:11:38

0:11:38

0:11:01

0:11:01

0:13:55

0:13:55

0:14:13

0:14:13

0:14:37

0:14:37

0:11:40

0:11:40

0:17:28

0:17:28

0:00:15

0:00:15

0:00:58

0:00:58

0:08:24

0:08:24

0:00:41

0:00:41

0:18:26

0:18:26

0:00:56

0:00:56

0:17:27

0:17:27

0:01:00

0:01:00