filmov

tv

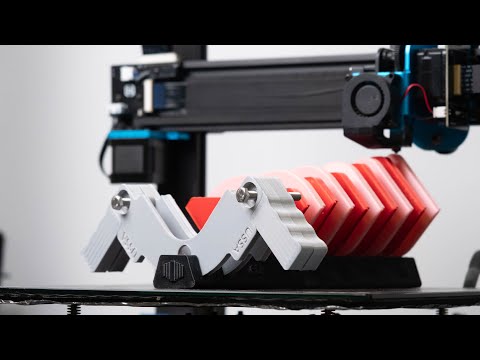

3D Printing for Woodworking || Multifunctional Edge Guide

Показать описание

3D printed Edge Guide designed in Rhino3d with grasshopper printed with PLA. It can be used in 3 different ways: with router table and two difefrent types of bits with bearing on top and bottom. Has 10 templates with difefrent radius and 45 degree cut ranging between 10 and 60mm radius.

3d printers used :

Camera gear:

#woodworking

#DIY

#3dprinting

#ender3v2

#sidewinderx1

#artilleryx1

3d printers used :

Camera gear:

#woodworking

#DIY

#3dprinting

#ender3v2

#sidewinderx1

#artilleryx1

10 AMAZING Woodworking Prints That Justify a 3D Printer

3d Printing For Woodworkers / 3D Printers Solve Problems In The Workshop / Improve Your Workflow

3D Printing For Woodworking Workshop With Budget Friendly 3D Printer Longer LK5 Pro | Free Download

3D Printing for Woodworkers - Beginners Guide

10 Things Every Woodworker Needs To 3D Print!

10 Things Every Woodworker Needs To 3D Print!

EASY shop organization with a 3d printer

3D Print Tools Instead of Buying Them

28(ish) 3D Printed Tools That Are ACTUALLY Useful!

12 more 3D printed tools you need for your workshop

Top 5 Amazing DIY Equipment || 3D Printed

3D Printed Tools #5 - Useful and Functional 3D Prints

12 3D printed tools you need for your workshop

Challenging Woodworking with 3D Printing: Best Projects of 2023

The Future of Woodworking is NOT What You Think!

3D Printing for Woodworking || Multifunctional Edge Guide

Top 10 3d printing projects for the woodworking workshop

I tried this massive 3d printer so you don't have to

Why you should have a 3D printer for your woodshop

How I Brought my Dream to Life || From Idea to Kickstarter

The Secret Tool Every Modern Woodworking Shop Needs: 3D Printers

3D Printed Furniture || Top 5

5 Awesome 3D PRINTS for WOODWORKING // TheTranq

Organizing my Drawer with 3D Printing

Комментарии

0:08:23

0:08:23

0:08:39

0:08:39

0:11:53

0:11:53

0:13:52

0:13:52

0:11:55

0:11:55

0:09:06

0:09:06

0:08:52

0:08:52

0:22:30

0:22:30

0:21:42

0:21:42

0:15:38

0:15:38

0:08:32

0:08:32

0:09:47

0:09:47

0:16:59

0:16:59

0:06:41

0:06:41

0:23:02

0:23:02

0:10:02

0:10:02

0:04:52

0:04:52

0:15:06

0:15:06

0:09:29

0:09:29

0:18:08

0:18:08

0:12:25

0:12:25

0:07:41

0:07:41

0:06:24

0:06:24

0:09:02

0:09:02