filmov

tv

I tried this massive 3d printer so you don't have to

Показать описание

This 3d printer is massive! This is my first try with the Elegoo Orange Storm Giga, a 3d printer capable of printing 800x800x1000mm.

Above links are affiliate links, it means I may get a small percentage at no extra cost to you.

SOCIAL:

Above links are affiliate links, it means I may get a small percentage at no extra cost to you.

SOCIAL:

I tried this massive 3d printer so you don't have to

HUGE Prints REALLY Fast! // MASSIVit 3D 1800 Pro Deep Dive!

GIGANTIC 3D Printed Building (it’s a Walmart)

How Concrete Homes Are Built With A 3D Printer | Insider Art

PS5 System Update: HUGE Home Screen Upgrade, Adaptive Charging, Custom 3D Audio, & More

GIANT 3D PRINTER FROM SCRATCH MkIV - BIGGER!

3D digital billboard image of a giant cat draws attention in Tokyo

GIANT 3D PRINTER FROM SCRATCH - IT WORKS!

Creating HUGE 3D ART from a Comic Book Cover

GIANT DIY 3D PRINTER FROM SCRATCH

Extreme Resin Stacking 3D Prints - This is wild!

We Test $300 vs $300,000 3D Printer

BigRep ONE: Industrial Large-Format 3D Printer for Prototypes, Molds, Tooling, and End Use Parts

This shouldn't work but it did - Multi Material 3D Prints

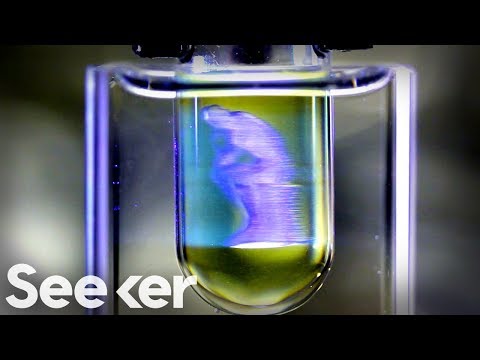

Why This 3D Light Printer Is a HUGE Game Changer

HUGE 3D Printed Dwarf (Uten Ironhearth) | Printing + Assembling + Painting

Giant 3D-printer builds a TWO-STORY house in one piece 🏡

3D Printer Gearbox - Spinning it FAST

I 3D Printed a 6000 pound Statue of MYSELF - Ultimate Prank!!

Building a Large Format 3D Printer – Part 1: Pellet Extruder

I Bought the 5 Cheapest 3D Printers on Amazon

My Genshin sword took 150h to 3D print! ⚔️ #diycrafts #cosplay

BIG HOLE LAVA ALL THE SONIC TAPES FAMILY VS VS ALL ZOONOMALY MONSTERS SPARTAN KICKING in Garry'...

I tried Injection Molding using a 3D Printer!

Комментарии

0:15:06

0:15:06

0:08:37

0:08:37

0:15:38

0:15:38

0:05:33

0:05:33

0:06:09

0:06:09

0:25:53

0:25:53

0:01:50

0:01:50

0:14:54

0:14:54

0:15:14

0:15:14

0:12:00

0:12:00

0:13:59

0:13:59

0:17:18

0:17:18

0:02:59

0:02:59

0:07:20

0:07:20

0:05:13

0:05:13

0:16:37

0:16:37

0:03:30

0:03:30

0:06:56

0:06:56

0:24:49

0:24:49

0:26:11

0:26:11

0:12:32

0:12:32

0:01:01

0:01:01

1:28:43

1:28:43

0:18:27

0:18:27