filmov

tv

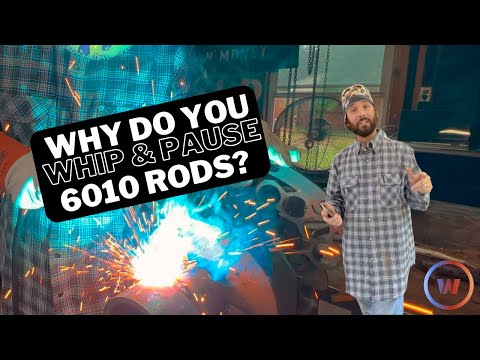

Welding with 6010: how to whip and pause

Показать описание

In this episode I cover how to whip and pause/stitch weld/etc, with 6010. This info will also work for 6011.

0:00:00 Intro

0:01:40 The technique

0:10:31 Let’s weld

0:29:39 The cut & etch and results

0:00:00 Intro

0:01:40 The technique

0:10:31 Let’s weld

0:29:39 The cut & etch and results

STICK WELDING for Beginners | SMAW 6010 & 7018

Welding with 6010: how to whip and pause

Why Do You Whip & Pause When Welding With A 6010 Rod?

Stick Welding Basics - How to Run Straight Consistent Beads

3 Stick Welding Electrodes Compared: 6013 vs 7018 vs 6010

HOW TO WELD WITH 6010 / 6011 ARC WELDING RODS - FREE LESSON - INCLUDING BONUS DESTRUCTIVE BEND TEST

Stick welding with 6010: Intro 🔥🐉

Stick Welding Techniques 6010 Downhill

The Do’s and Don’ts of 6010 ~ Tulsa Welding School

6010 Root Pass | 3g Plate | SMAW

6010 Open Root Welding | Quit Blowing Holes In Your Plate

Welding 6010 Uphill Techniques | Stick Welding Tips and Tricks for Beginners

6010 & 7010 Overhead Root Practice Plate

Stick Welding: #1 Beginner Mistake and How to Fix It

The First Lesson of Welding | Learning to Run Beads

Stick Welding Tips for 6010 Open Root &7018 fill cap

5G Pipe Welding On 8' - 6010 & 7018 Weld

6010 welding ain't easy, but at MWI, we're here to help you master it! #welding #best #fyp...

Welding with 6010 on AC

🔥 6010 Roots and Bad Fit-up

Pipe Welding for Iron Workers | 6010 Open Root

6g Weld Test 6010 Root

Stick Welding Rod Overview

6010 ROOT TIPS & TRICKS | VERY DETAILED, HIGHLY REQUESTED PIPE WELDING

Комментарии

0:21:19

0:21:19

0:34:08

0:34:08

0:05:30

0:05:30

0:13:50

0:13:50

0:09:41

0:09:41

0:10:47

0:10:47

0:33:04

0:33:04

0:10:39

0:10:39

0:15:48

0:15:48

0:04:58

0:04:58

0:11:37

0:11:37

0:02:58

0:02:58

0:07:40

0:07:40

0:06:06

0:06:06

0:10:10

0:10:10

0:08:26

0:08:26

0:33:10

0:33:10

0:00:58

0:00:58

0:13:37

0:13:37

0:14:27

0:14:27

0:13:31

0:13:31

0:10:30

0:10:30

0:09:02

0:09:02

0:06:57

0:06:57