filmov

tv

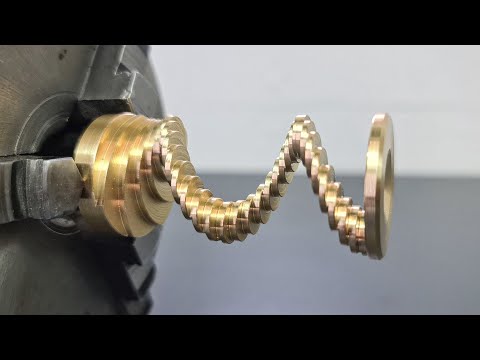

The 6 Best Lathe Projects For Beginners

Показать описание

G'day everyone,

I have been working on this years major project, and it has been taking longer than expected. I was planning on releasing part one this week, but a few things got in the day so I have decided to delay it a week, rather than try and rush it.

So I had a good thought about what projects I would recommend to someone who is getting started with lathe-ing. Somewhat difficult because we pick things up at a different rate, but I have a short list of projects I think would be a good fit. Most of them revolve around lathe tools, which is good because once you are finished you get a tool that you will actually use.

If you think that I have missed a good project let me know in the comments. Cheers

#machining #lathe

Top lathe Projects

Beginner Lathe Projects

Metal Lathe Projects

Timestamps

0:00 - Intro

0:57 - Half Centre (Very Easy)

3:45 - Scriber (Easy)

5:17 - Machinist Hammer (Easy)

7:25 - Tap Follower (Medium)

10:38 - Tailstock Die Holder (Medium)

12:46 - Carriage Stop (Mill Required)

Mini Lathe - Sieg c3 7x14 Mini Lathe

Mill - Sieg x2.7l

Big Lathe - Hafco Al 250G

I have been working on this years major project, and it has been taking longer than expected. I was planning on releasing part one this week, but a few things got in the day so I have decided to delay it a week, rather than try and rush it.

So I had a good thought about what projects I would recommend to someone who is getting started with lathe-ing. Somewhat difficult because we pick things up at a different rate, but I have a short list of projects I think would be a good fit. Most of them revolve around lathe tools, which is good because once you are finished you get a tool that you will actually use.

If you think that I have missed a good project let me know in the comments. Cheers

#machining #lathe

Top lathe Projects

Beginner Lathe Projects

Metal Lathe Projects

Timestamps

0:00 - Intro

0:57 - Half Centre (Very Easy)

3:45 - Scriber (Easy)

5:17 - Machinist Hammer (Easy)

7:25 - Tap Follower (Medium)

10:38 - Tailstock Die Holder (Medium)

12:46 - Carriage Stop (Mill Required)

Mini Lathe - Sieg c3 7x14 Mini Lathe

Mill - Sieg x2.7l

Big Lathe - Hafco Al 250G

Комментарии

0:14:19

0:14:19

0:03:08

0:03:08

0:00:16

0:00:16

0:28:43

0:28:43

0:26:20

0:26:20

0:01:53

0:01:53

0:03:59

0:03:59

0:10:07

0:10:07

0:15:33

0:15:33

0:16:46

0:16:46

0:03:14

0:03:14

0:08:21

0:08:21

0:00:32

0:00:32

0:18:37

0:18:37

0:06:34

0:06:34

0:08:09

0:08:09

0:04:15

0:04:15

0:01:36

0:01:36

0:14:23

0:14:23

0:09:06

0:09:06

0:00:28

0:00:28

0:03:54

0:03:54

0:00:15

0:00:15

0:03:11

0:03:11