filmov

tv

How to reduce 3D printing filament waste by using the SUNLU filament connector FC01

Показать описание

Affiliate links:

SUNLU FC01 Filament Connector:

Aurora Tech Channel 3D Printer Price Tracker and recommendation list:

3d Model:

Trash can:

SUNLU FC01 Filament Connector:

Aurora Tech Channel 3D Printer Price Tracker and recommendation list:

3d Model:

Trash can:

Stop 3d printing so slow!!! 🤯 (how to print faster)

The Ultimate Guide to Perfect 3D Prints

5 must-know 3D printing tips & tricks. (stronger and better looking prints)

How To Fit ANY 3D Model on ANY 3D Printer! - A Cutting and Slicing Tutorial

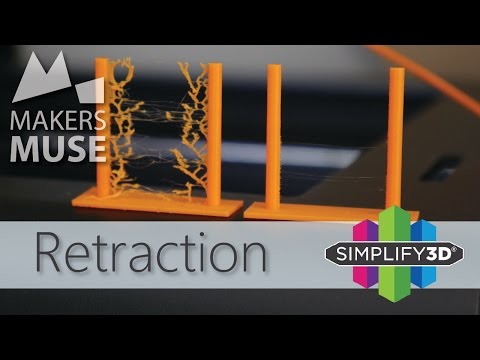

Stop the stringing with Retraction! 3D Printing 101

5 3D Printing Tips the ELITES don't want you to know... #3DP101

Stop Stringing when 3d printing! How to reduce or solve stringing on a 3d printer -cura or otherwise

How to STOP Elephant's Foot on your 3D Prints

Upgrading my Bionicles with 3D Printing

How People BREAK 3D Printers (and how to stop it)

3D Print Not Sticking? 9 Ways to Get Perfect Bed Adhesion

Creality Ender 3 V2 - Simple Tips for Super Clean 3D Prints

Have your 3D Prints started to suck? Watch this!

So Smooth... Ironing Settings in Cura for Perfect Top Layers - 3D Printer Pro Tips

Understand WHY 3D prints WARP - Simple explanation with experiment!

3D Print parts TWICE as fast with simple slicer tweaks. 3DP101

3D Printer Blobs: a mysterious problem you won't guess how to fix 🤔

Better First Layer and Bed Level Fixes on 3D Printers

An EASY Way to Cut & Separate 3D Printing Files into MULTIPLE PARTS!

Ghosting in 3D Prints - What is it and how do you fix it?

How to 3D Print Flexible Filament in 20 seconds

Improve your prints with acetone smoothing

How to Resume an Unfinished/Failed 3D Print! (EASY FIX!)

Best Way to Get Rid of Stringing on 3D Prints Using Cura + Get Smooth Top Layer + Block Supports

Комментарии

0:04:14

0:04:14

0:17:27

0:17:27

0:02:44

0:02:44

0:26:17

0:26:17

0:05:14

0:05:14

0:07:26

0:07:26

0:12:44

0:12:44

0:13:55

0:13:55

0:12:40

0:12:40

0:16:22

0:16:22

0:06:41

0:06:41

0:08:26

0:08:26

0:20:04

0:20:04

0:06:06

0:06:06

0:01:38

0:01:38

0:14:42

0:14:42

0:08:27

0:08:27

0:04:47

0:04:47

0:15:38

0:15:38

0:05:50

0:05:50

0:00:20

0:00:20

0:04:31

0:04:31

0:10:20

0:10:20

0:16:50

0:16:50