filmov

tv

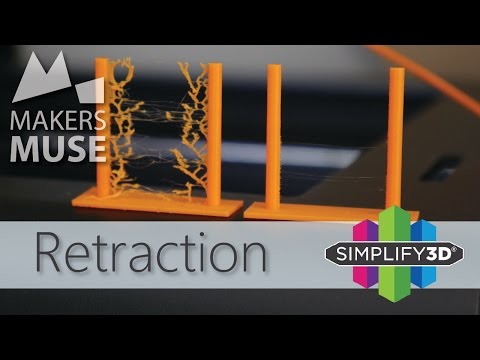

Stop the stringing with Retraction! 3D Printing 101

Показать описание

Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3D Prints, but it's very misunderstood! In this 3D Printing 101 we'll go through the basics of what retraction settings are and how you can tweak them.

You'll be amazed by how much of a difference correct retraction can make!

Don't forget to subscribe so you don't miss any future 3D Printing Reviews, Tutorials or Projects!

---

Like what we do?

Say G'day to us on Twitter and Instagram @makersmuse

Ways you can support Maker's Muse:

-Want to buy a 3D Printer but don't know where to start? Get our eBook here!

- Support us on Patreon

-Buy a T-shirt!

- By using our amazon affiliate links

Or a direct donation through Youtube

And lastly, a BIG thanks to the community, and those who have supported us here at Makers Muse!

----

You'll be amazed by how much of a difference correct retraction can make!

Don't forget to subscribe so you don't miss any future 3D Printing Reviews, Tutorials or Projects!

---

Like what we do?

Say G'day to us on Twitter and Instagram @makersmuse

Ways you can support Maker's Muse:

-Want to buy a 3D Printer but don't know where to start? Get our eBook here!

- Support us on Patreon

-Buy a T-shirt!

- By using our amazon affiliate links

Or a direct donation through Youtube

And lastly, a BIG thanks to the community, and those who have supported us here at Makers Muse!

----

Stop the stringing with Retraction! 3D Printing 101

Stop Stringing With These Retraction Settings

Stop Ender 3 Stringing with this One Weird Trick! (ok but seriously)

Creality Ender 3 V2 - Stop Stringing, Improve Print Quality & Time With These Two Settings

How to Fix Stringing on a 3D Printer

Stringing Nightmares: How Cura's Travel Settings Can Save 3D Prints

Best Way to Get Rid of Stringing on 3D Prints Using Cura + Get Smooth Top Layer + Block Supports

Say Goodbye To Stringing Forever - 3D Printing Tips!

Stop Stringing when 3d printing! How to reduce or solve stringing on a 3d printer -cura or otherwise

Cura Settings for Retraction and Raft on Creality Ender 3 or CR-10 Mini

Calibrate Perfect Retraction Settings Using a Cura 4.8 Plug-in

Get Rid of That Silly Stringing With Retraction

Change This Setting To Removed PLA Stringing

Quick Fix to Eliminate Stringing on your 3D Prints

SOLUTION AND TIPS TO FIX STRINGING ISSUE

Fix Stringing Once And For All

Retraction Calibration

OrcaSlicer Retraction Tuning To Avoid Stringing

Get Rid Of That Stringing In Creality Print

5 Quick Tips to Stop Stringing In Its Tracks

The easiest way to get rid of 3d print stringing with TPU

The secret to 3D printing PETG [Adventurer 4]

This setting might actually be ruining your prints, instead of helping them.

Creality Ender 3 V2 - Fixing the Hidden Problem that Can Cause Stringing and Unresponsiveness

Комментарии

0:05:14

0:05:14

0:02:01

0:02:01

0:15:30

0:15:30

0:04:38

0:04:38

0:09:57

0:09:57

0:37:07

0:37:07

0:16:50

0:16:50

0:03:58

0:03:58

0:12:44

0:12:44

0:05:39

0:05:39

0:07:48

0:07:48

0:06:28

0:06:28

0:07:03

0:07:03

0:05:59

0:05:59

0:04:05

0:04:05

0:01:58

0:01:58

0:04:55

0:04:55

0:13:32

0:13:32

0:05:19

0:05:19

0:03:56

0:03:56

0:01:52

0:01:52

0:13:45

0:13:45

0:14:28

0:14:28

0:06:07

0:06:07