filmov

tv

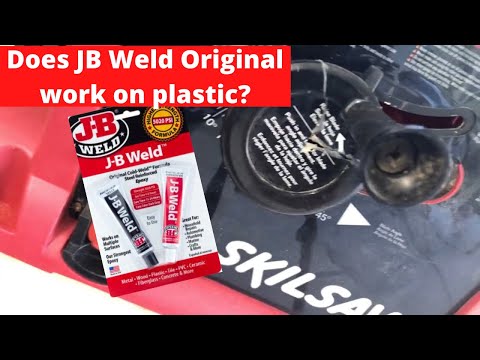

Jb Weld Can Repair Steel - Aluminum - Anything

Показать описание

Many of our videos are comedic & satirical & not intended to cultivate antisocial or unlawful behavior. Thank you for supporting our Channel through the below affiliate links. No price increase for you but we may receive compensation.

Become A Wranglerstar Member For Exclusive Content and Perks

#Proho #wranglerstar

Become A Wranglerstar Member For Exclusive Content and Perks

#Proho #wranglerstar

How to Use JB Weld SteelStik | Step-by-Step Instructions

How to use JB Weld | JB Weld Original Cold Steel | JB Weld Step-by-Step Instructions

How to use JB Weld Original Cold Weld Steel Reinforced Epoxy, plus Review

How strong is JB weld structural epoxy adhesive anyways ? Destructive test, simulation and review

JB Weld SteelStik Review-Real Life Use

JB Weld Original Cold Steel VS JB Weld Kwikweld Head to Head Comparison

JB Weld Strength Test

JB Weld Tips

Is JB Weld Strong Enough to Repair a Broken Connecting Rod? Let's Find Out!

How JB Weld SAVED My Metal Patio Furniture + Trick to Add Strength

How to Use JB Weld Clearweld Step-by-step Instructions

How to use JB Weld | JB Weld Original Cold Steel | JB Weld Step-by-Step Instructions

You Can GLUE Metal — Repair Metal w NO Welding w JB Weld

The Ultimate JB Weld Strength Test (Lifting a Car)

How to Use JB Weld on Small Repairs | JB Weld Delicate Metal Repair

Does JB Weld work on plastic?

The Best Way To Use JB Weld

J-B Weld FiberWeld Repair Cast

What is J-B Weld for? How To Repair With J-B Weld

HOW TO USE J-B WELD SYRINGE EPOXIES AND ADHESIVES

How to Use JB Weld

JB Weld Metal Repair Paste Reviews - Does it Really Work?

How To Use J-B Weld Epoxy Putty Sticks

J B Weld Steelstik

Комментарии

0:03:49

0:03:49

0:03:46

0:03:46

0:01:53

0:01:53

0:09:19

0:09:19

0:06:15

0:06:15

0:02:14

0:02:14

0:04:05

0:04:05

0:02:28

0:02:28

0:05:31

0:05:31

0:08:05

0:08:05

0:01:38

0:01:38

0:02:11

0:02:11

0:02:48

0:02:48

0:12:40

0:12:40

0:01:45

0:01:45

0:02:32

0:02:32

0:06:14

0:06:14

0:01:03

0:01:03

0:05:39

0:05:39

0:00:53

0:00:53

0:01:54

0:01:54

0:00:24

0:00:24

0:00:49

0:00:49

0:09:38

0:09:38