filmov

tv

CNC Router Bits Explained: The Best Bit To Use

Показать описание

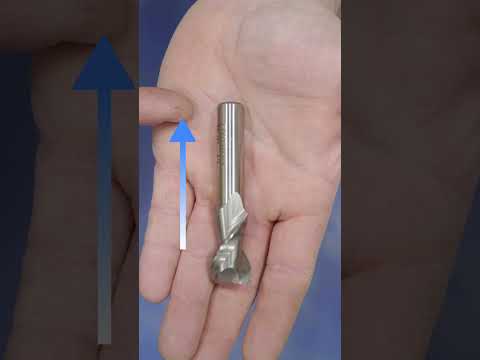

CNC router bits can be confusing. In this video, I explain and show the differences between an upcut, downcut, and compression bit.

Support Andy Bird Builds Channel

Tools To Help You Make Money With Your CNC

Interested in getting started in CNC, but don't know where to start?

A great way to support Andy Bird Builds is to purchase through affiliate links, you get what you need and I may get a kickback!

Support Andy Bird Builds Channel

Tools To Help You Make Money With Your CNC

Interested in getting started in CNC, but don't know where to start?

A great way to support Andy Bird Builds is to purchase through affiliate links, you get what you need and I may get a kickback!

CNC Router Bits Explained: The Best Bit To Use

Beginners Guide to CNC Bits - Including Speeds and Feeds

CNC Router Bits Tutorial - Everything You Need To Know

Which CNC Bits Do You ACTUALLY Need? - Andy Bird Builds Bits Revealed!

CNC Bits For Beginners / Upcut Vs. DownCut Vs. Compression Vs. Ball Nose End Mills!

CNC Router Bits for Beginners

Spiral Bits - Compression VS Upcut VS Downcut VS Straight - Never Before Seen 19,000 FPS HD Video

Calculating Feeds and Speeds A Practical Guide | Wood CNC Router

CNC Routers - Feeds and Speeds EXPLAINED For Beginners, CNC Router Bits Feeds and Speeds

What CNC Router Bits Do Beginners Need?

5 Best CNC Bits for Beginners (Don’t Buy the Wrong Ones!)

Best CNC Router Bits & Tools For Beginners, Good CNC route bit set

Siansmart CNC Router Bits, What Are They For? - Garrett Fromme

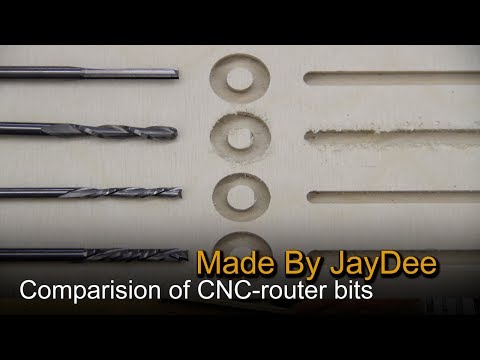

Comparison of 4 different CNC endmill router bits

Cheap CNC Router Bits on Amazon: A Risk You Shouldn't Take?

My top 3 most used CNC Router bits, what are yours?👉#shorts

Genmitsu MRBC08 End Mills CNC Router Bits, for Carving Aluminum, Metal, Plastic, MDF & Wood

CNC Vbits for Beginners

When to Use Spiral vs. Straight Router Bits

Spiral Router Bits Explained

Getting Started with CNC Machines - Choosing Bits

CNC Router Bit Types and Their Uses

SUPER Smooth: Use Bowl Bits on YOUR CNC Router - CNC Tutorial

CNC Router Feeds & Speeds for Wood – Beginners Guide

Комментарии

0:11:14

0:11:14

0:33:28

0:33:28

0:49:34

0:49:34

0:08:01

0:08:01

0:08:51

0:08:51

0:14:04

0:14:04

0:12:26

0:12:26

0:12:34

0:12:34

0:15:02

0:15:02

0:00:51

0:00:51

0:20:58

0:20:58

0:15:24

0:15:24

0:07:56

0:07:56

0:06:12

0:06:12

0:22:56

0:22:56

0:00:11

0:00:11

0:00:20

0:00:20

0:06:59

0:06:59

0:00:39

0:00:39

0:04:21

0:04:21

0:05:47

0:05:47

0:28:53

0:28:53

0:08:12

0:08:12

0:22:21

0:22:21