filmov

tv

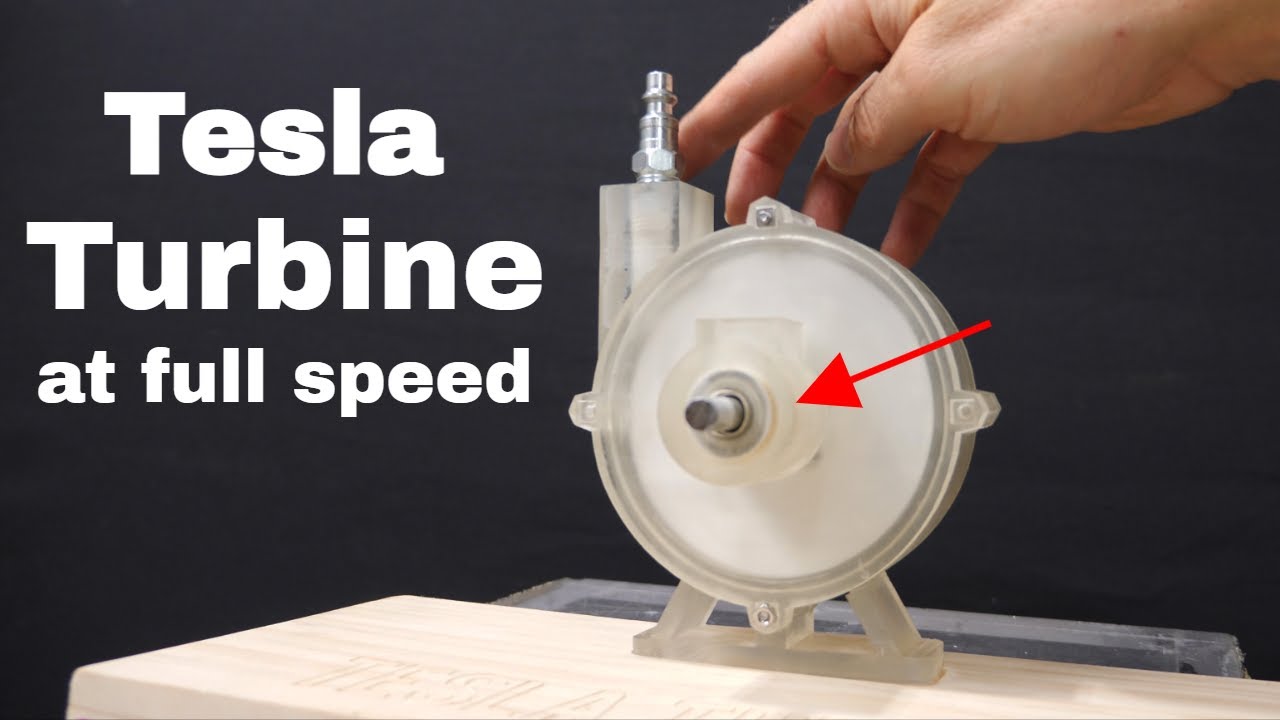

How Fast Can a Tesla Turbine Spin?

Показать описание

I show you how the tesla turbine works

How fast my tesla charges 😂

Is The Tesla REALLY That Fast?!

How Much Does it Cost To Supercharge My Tesla?? 💵😬

How Fast is the New American Made Tesla Model 3?

How Long Does It Take To Charge A Tesla?

Charging A Tesla Model 3 - How Long Does it Take?? - Real World Tesla Supercharging - Timed Demo!

Tesla Supercharging Basics in 30 seconds #shorts

How Fast Can a Tesla Turbine Spin?

Real Range Test – How Far Can the ZEEKR 001 Go?@AutoVelocityAli_ t9y

Tesla Model S Plaid Launch

2023 Tesla Model S Plaid 0-60 MPH 0-130 MPH launch #acceleration #tesla #plaid

This Tesla Had A Major Issue...

Does a Tesla charge faster than a Rivian Short

How fast can the Tesla Bot run?, Can Tesla Optimus talk and perform routine tasks?

Tesla Model S Plaid 0-100MPH Launch! 😱 #shorts

Tesla Roadster 1.8 Sec from 0-100

How much it costs to charge a Tesla Model X at a Tesla Supercharger

Did you know you can unlock a tesla with your voice?? 😳👀

Tesla Autopilot Driving DOUBLE the Speed Limit!

How do you pay for electricity when charging a Tesla on the road? #tesla

Tesla Model S Plaid's Insane Acceleration from 0-328 KM/H on the Autobahn #shorts #tesla

2024 Tesla Roadster Plaid SPACEX Pkg 0-217mph IS HYPERSONIC FAST😳🤯🤯 #Shorts

Tesla’s Battery went to 0% How low would you drive your Tesla before charging #shorts

Autopilot Top Speed in Electric Mercedes CRUSHES Tesla!

Комментарии

0:00:18

0:00:18

0:00:48

0:00:48

0:00:30

0:00:30

0:00:45

0:00:45

0:00:22

0:00:22

0:05:06

0:05:06

0:00:30

0:00:30

0:05:33

0:05:33

0:00:55

0:00:55

0:00:21

0:00:21

0:00:17

0:00:17

0:00:26

0:00:26

0:00:36

0:00:36

0:01:05

0:01:05

0:00:10

0:00:10

0:00:09

0:00:09

0:00:25

0:00:25

0:00:24

0:00:24

0:00:13

0:00:13

0:00:34

0:00:34

0:00:29

0:00:29

0:00:17

0:00:17

0:00:34

0:00:34

0:00:20

0:00:20