filmov

tv

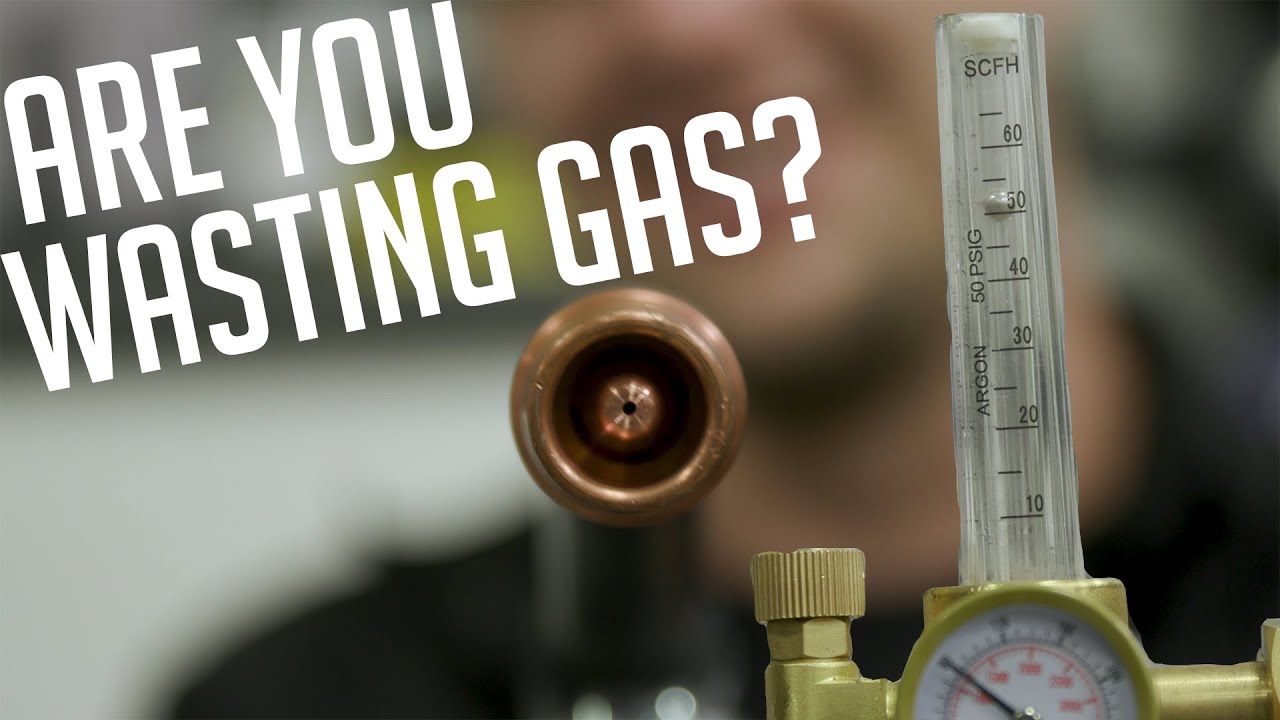

4 Easy Tips to Save Gas

Показать описание

#welddotcom

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

4 Easy Tips to Save Money

#BDJPlanWithMe 4 Easy Tips to Save Money

4 Easy Tips to Save Gas

Simple Habits to Save Money During Every Season of the Year!

4 Easy Tips to Save Money #shorts

How to Start Saving Effortlessly: 4 Easy Tips

Top 4 - Easy energy saving tips for your household in winter

4 Easy Money Saving Tips

10 EASY & PRACTICAL money saving tips for 2024

3 easy study tips 📚✨✍️

How to save money | 4 Easy Saving Money Tips To Get Started

How to Save Money (5 Easy Tips)

9 Steps to Save $10,000 on a Low Income 💵 Money Saving Tips for 2025!

Save more money than ever! 4 EASY TIPS

50 Ways to SAVE MONEY with Minimalism | Easy Money Saving Tips

Saving money at university // 10 EASY tips

7 Easy Tips to Save $1000 in Just One Month!

Easy clothes folding tips 4 #fashion #clothfolding #foldinghacks #homehacks #diy

Learn this parking trick and parking is easy!#car #shorts #driving #tips #tutorial

EASY FRUGAL TIPS TO SAVE MONEY FAST | Frugal Habits That Actually Work | FRUGAL LIVING TIPS

Right way to defrost Chicken quickly 😲 | Easy Kitchen tips & hacks | #shorts #kitchenhacks

Realistic & Minimalist House Tour + 4 Easy Tips To Keep A Tidy Home

Parallel Parking Made Easy: Learn the One Second Trick | Driving Tips #tips #tricks #obdgo #cartips

Three Easy Tips to Dressing Simple and Stylish | See Pinned Comment for More #capsulewardrobe #style

Комментарии

0:00:51

0:00:51

0:03:01

0:03:01

0:05:55

0:05:55

0:25:45

0:25:45

0:00:26

0:00:26

0:05:23

0:05:23

0:01:29

0:01:29

0:00:26

0:00:26

0:16:25

0:16:25

0:00:13

0:00:13

0:06:19

0:06:19

0:11:21

0:11:21

0:21:07

0:21:07

0:07:52

0:07:52

0:30:31

0:30:31

0:05:58

0:05:58

0:00:48

0:00:48

0:00:15

0:00:15

0:00:12

0:00:12

0:15:51

0:15:51

0:00:37

0:00:37

0:09:02

0:09:02

0:00:40

0:00:40

0:00:41

0:00:41