filmov

tv

Free Electricity - Micro Hydro - Prof Simon

Показать описание

Is it possible to build your own Archimedes water powered micro hydro generator? I had a go with a few off the shelf parts.

leave a like, ask a question and subscribe for more. - Thanks 'Prof' Simon.

Join my science film club - ADVERT free, early access films and OPEN non Censored discussion with me and other supporters. from only $3 per month. or *** join TODAY for a FREE trail.

link to the home built micro hydro generator project.

leave a like, ask a question and subscribe for more. - Thanks 'Prof' Simon.

Join my science film club - ADVERT free, early access films and OPEN non Censored discussion with me and other supporters. from only $3 per month. or *** join TODAY for a FREE trail.

link to the home built micro hydro generator project.

Free Electricity - Micro Hydro - Prof Simon

Generate Free Energy with Mini Hydro Generators

Micro Hydro Turbine Test #free #energy #science #experiment

DIY Micro Hydro Power Plant: How to Harness Stream Energy for Electricity #renewableenergy

Unleashing the Power of Water: Micro Hydro Generator for Clean Energy Generator

Lifetime Water Turbine Free Generator #shortsvideo #experiment #shortsfeed #generator #freeenergy

hydro electric water turbine free energy 10 kw

Owuh F50 Micro-hydro DC Water Flow Pump Turbine Hydroelectric Power Energy Generator

Diy Micro Hydro-Power Plant With Turbine System

hydro power generator

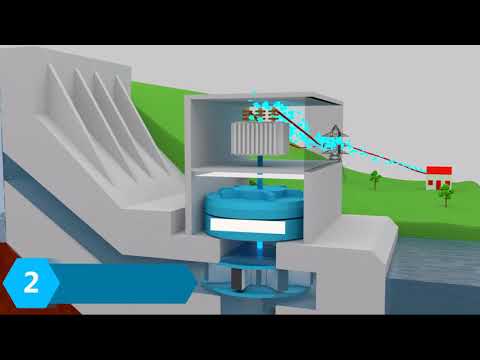

hydroelectric power plant | Francis turbine | free energy | water turbine

Micro Hydro Power Generation - Free Energy!

Hydroelectric power plant Animation

Mini-Hydro Power Plant

DIY mini hydro power/homemade hydro electric power

Mini Hydro Electric Power Plant

high RPM hydro power

Can a Waterwheel Generate Electricity?

Off Grid Micro Hydro - Building a 6kW Off Grid EMPIRE

Power Your Homestead with Water: Step-by-Step Guide to Building a Hydro Generator

Micro hydro turbines | DIY | Homemade Hydro Electric Station! Alternative energy! Free Electricity

This innovative waterwheel generates clean electricity from a river.

The Most Profitable Micro Hydro-power Plant

AWESOME WATER POWER 500w Hydro Electric Off Grid System

Комментарии

0:04:39

0:04:39

0:00:15

0:00:15

0:00:54

0:00:54

0:00:07

0:00:07

0:00:09

0:00:09

0:00:15

0:00:15

0:00:53

0:00:53

0:00:14

0:00:14

0:00:32

0:00:32

0:00:30

0:00:30

0:00:22

0:00:22

0:08:17

0:08:17

0:00:17

0:00:17

0:00:27

0:00:27

0:00:16

0:00:16

0:00:15

0:00:15

0:00:13

0:00:13

0:00:32

0:00:32

0:29:35

0:29:35

0:00:59

0:00:59

0:01:28

0:01:28

0:00:57

0:00:57

0:00:39

0:00:39

0:16:55

0:16:55