filmov

tv

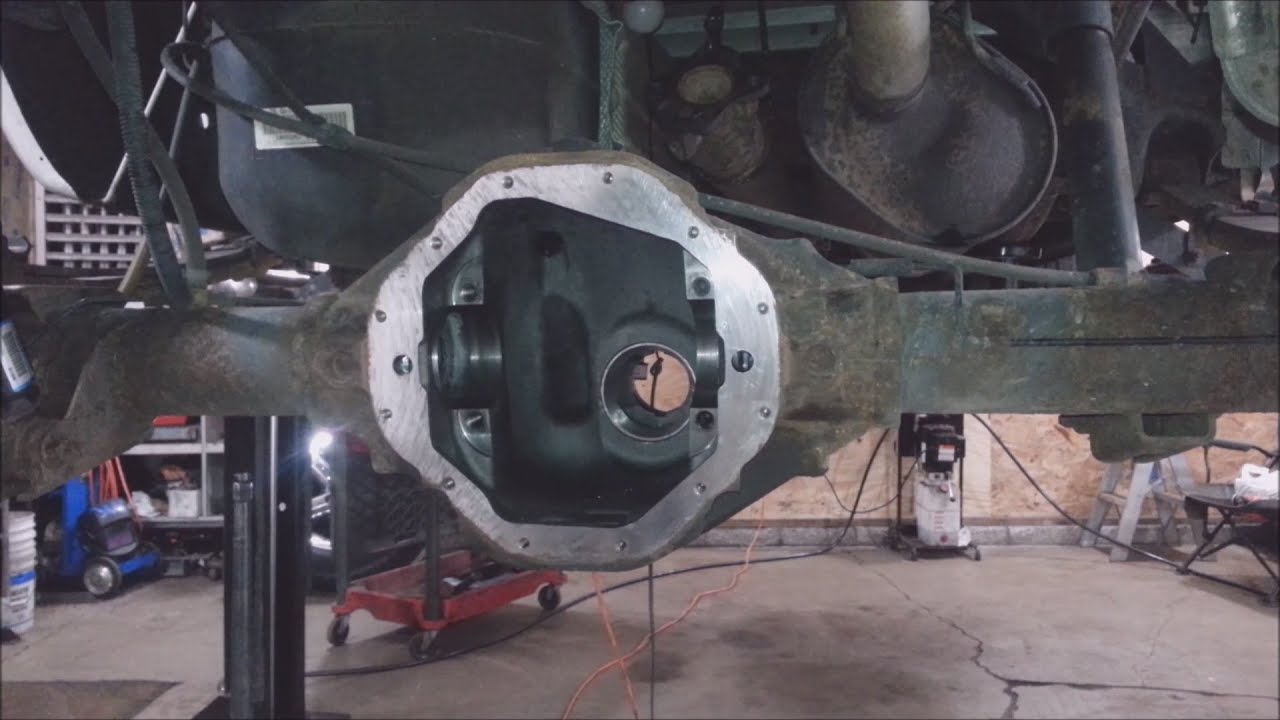

1994-2018 Ram 1500 9.25' rear differential rebuild assembly pt2

Показать описание

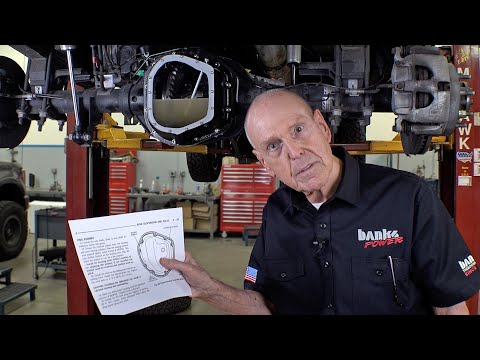

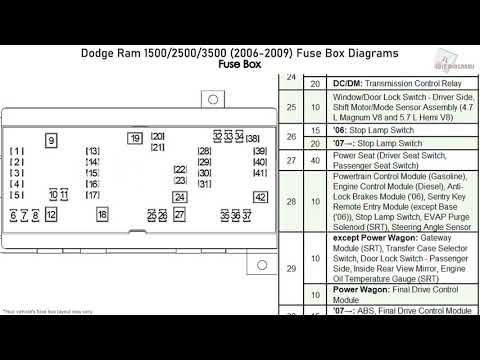

How to fix axle and pinion bearings. This was a 2008. These Dodge axles are pretty much the same from 1994-2018, I do believe. Check your specifications for differences. 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2009 2010 2011 2012 2013 2014 2015 2016 2017. 94 95 96 97 98 99 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18

Disclaimer:

Due to factors beyond the control of Rust Belt Auto, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. Rust Belt Auto assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. Use this video at your own risk. Rust Belt Auto recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of Rust Belt Auto, No information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained.

Disclaimer:

Due to factors beyond the control of Rust Belt Auto, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. Rust Belt Auto assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. Use this video at your own risk. Rust Belt Auto recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of Rust Belt Auto, No information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained.

Комментарии

0:13:37

0:13:37

0:13:09

0:13:09

0:04:44

0:04:44

0:00:30

0:00:30

0:00:26

0:00:26

0:04:56

0:04:56

0:01:56

0:01:56

0:10:26

0:10:26

0:00:25

0:00:25

0:01:28

0:01:28

0:02:37

0:02:37

0:13:01

0:13:01

0:00:12

0:00:12

1:05:25

1:05:25

0:05:16

0:05:16

0:03:37

0:03:37

0:02:01

0:02:01

0:00:18

0:00:18

0:07:00

0:07:00

0:00:22

0:00:22

0:02:05

0:02:05

0:00:51

0:00:51

0:00:35

0:00:35

0:00:14

0:00:14