filmov

tv

Make Your Own Printed Circuit Boards Part 3 - Drill!

Показать описание

This is the third of my 3-part vlog mini-series on high quality PCB manufacturing. In these vlogs I will show the specialized tools and equipment that you will need to make your own high quality PCB's from scratch, with step by step demonstrations of each stage - from rendering and checking the artwork, to applying the resist to copper clap boards, to etching, to drilling the PCB's.

You can now PRINT PCBs! Creating a homemade PCB with the Voltera V-One PCB Printer!

PCB Creation for Beginners - Start to finish tutorial in 10 minutes

'A Machine PERFECT for Making PCBs at Home' Is what they said!

DIY PCBs At Home (Single Sided Presensitized)

How To Make Custom PCB's For Your Projects!

DIY PCB Fabrication (Dry Film Inkjet Method)

Make Your Own Printed Circuit Boards with SparkFun!

Design and Build a PCB - SMD LED Learn electronics engineering

Uni-Byte 0247 - VARIABLE DC Power Supply - Adding Current Control to the DESIGN: Part 3

Just print a PCB (HOW TO)

How To Make Your Own Printed Circuit Boards (PCB)

Make Your Own Printed Circuit Boards Part 1 - Artwork and Resist

Making Professional PCB at Home

How to Make a Circuit Board (Beginner's Guide)

Making a Circuit Board From Scratch

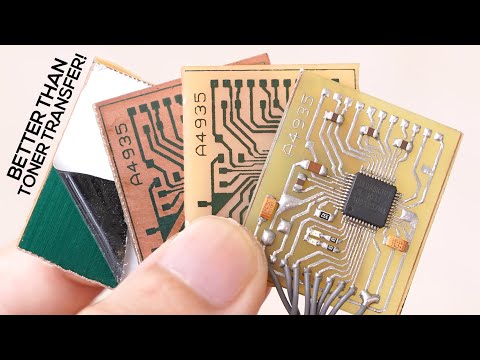

The fastest way to make crisp PCBs at home!

How to Design & PCB Etching- Part 2

The fastest way to make PCBs at home - UV MSLA Printer

DIY Simplified Arduino That Anyone Can Build

Make your own PCB with a sharpie!

Creating your own custom hardware (printed circuit boards)

Creating Your Own Printed Circuit Boards

Homemade PCB (printed circuit board)

Make Your Own Printed Circuit Boards Part 2 - Etching!

Комментарии

0:12:23

0:12:23

0:10:40

0:10:40

0:12:29

0:12:29

0:10:11

0:10:11

0:09:28

0:09:28

0:05:35

0:05:35

0:02:26

0:02:26

0:10:44

0:10:44

0:08:29

0:08:29

0:03:33

0:03:33

0:06:11

0:06:11

0:10:02

0:10:02

0:12:04

0:12:04

0:08:01

0:08:01

0:10:11

0:10:11

0:10:56

0:10:56

0:04:09

0:04:09

0:12:09

0:12:09

0:10:59

0:10:59

0:32:59

0:32:59

0:12:36

0:12:36

0:21:20

0:21:20

0:05:34

0:05:34

0:12:10

0:12:10