filmov

tv

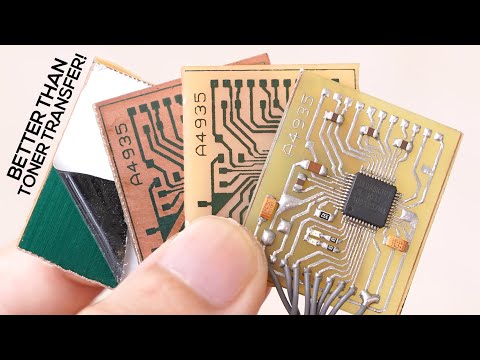

DIY PCBs At Home (Single Sided Presensitized)

Показать описание

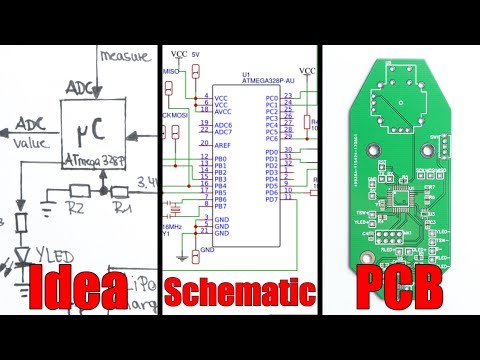

Learn to fabricate Single Sided PCBs at home! Prototype PCB fabrication is one of the essential skills you must learn in electronics. Instead of using breadboards and perfboards, custom PCBs would make any project smaller and more compact!

PRESENSITIZED PCBs:

Also known as photopositive PCBs or photoresist PCBs, are regular PCB copper clads, layered with a light sensitive paint or film. Once exposed to light, the paint would dissolve in the developing solution, while the unexposed areas would remain undissolved in the solution. This forms a Mask on the clad. When the developed PCB is exposed to an etchant, the masked areas would remain in tact while the unmasked areas would dissolve on your etchant, thus forming a copy of your printed PCB artwork.

WHAT PAPER AND PRINTER TYPE TO USE:

- You can use an injket printer for this type of PCB fabrication, no need for toner printers.

- I use regular Short Bond Paper (Letter 8.5x11"). You can use parchment paper or inkjet friendly films for better fabrication quality.

BETTER THAN TONER TRANSFER METHOD:

Toner transfer method has been the number 1 go to in homebrew PCB fabcrication, next to the sharpie method. Toner transfer has its own limitations. One, is that you would need a toner printer, common inkjet printers simply wouldn't work. Second, as your line traces gets thinner, it would be more difficult to transfer the toner prints to the copper clad. Presensitized PCBs on the other hand creates the sharpest lines of all the homebrew fabrication methods. This is perfect for smaller circuits that involves SMT (Surface Mount) components. I use this method for building PCBs with line traces reaching down to 10mils (0.254mm). You can go as thin as 5mils (0.1275mm), but you would have to use inkjet friendly acetate.

_______________________________

Instructable Tutorial:

DIY Etching PCB Shaker

DIY Digital PCB Exposure Box!

_______________________________

Tools & Materials:

1.) Photopositive PCB Pack

2.) Ferric Chloride (Copper Etchant)

3.) Pure Acetone (Nail Polish Remover)

4.) Baby Oil

5.) Mini Drill

6.) Drill Bits (0.8mm - 1.0mm)

7.) LED/ CFL/ UV Lamp

8.) Cutter Knife

9.) Hack Saw

10.) Wooden Plank

#Circuits #Electronics #DIY , Kinsten PCB

PRESENSITIZED PCBs:

Also known as photopositive PCBs or photoresist PCBs, are regular PCB copper clads, layered with a light sensitive paint or film. Once exposed to light, the paint would dissolve in the developing solution, while the unexposed areas would remain undissolved in the solution. This forms a Mask on the clad. When the developed PCB is exposed to an etchant, the masked areas would remain in tact while the unmasked areas would dissolve on your etchant, thus forming a copy of your printed PCB artwork.

WHAT PAPER AND PRINTER TYPE TO USE:

- You can use an injket printer for this type of PCB fabrication, no need for toner printers.

- I use regular Short Bond Paper (Letter 8.5x11"). You can use parchment paper or inkjet friendly films for better fabrication quality.

BETTER THAN TONER TRANSFER METHOD:

Toner transfer method has been the number 1 go to in homebrew PCB fabcrication, next to the sharpie method. Toner transfer has its own limitations. One, is that you would need a toner printer, common inkjet printers simply wouldn't work. Second, as your line traces gets thinner, it would be more difficult to transfer the toner prints to the copper clad. Presensitized PCBs on the other hand creates the sharpest lines of all the homebrew fabrication methods. This is perfect for smaller circuits that involves SMT (Surface Mount) components. I use this method for building PCBs with line traces reaching down to 10mils (0.254mm). You can go as thin as 5mils (0.1275mm), but you would have to use inkjet friendly acetate.

_______________________________

Instructable Tutorial:

DIY Etching PCB Shaker

DIY Digital PCB Exposure Box!

_______________________________

Tools & Materials:

1.) Photopositive PCB Pack

2.) Ferric Chloride (Copper Etchant)

3.) Pure Acetone (Nail Polish Remover)

4.) Baby Oil

5.) Mini Drill

6.) Drill Bits (0.8mm - 1.0mm)

7.) LED/ CFL/ UV Lamp

8.) Cutter Knife

9.) Hack Saw

10.) Wooden Plank

#Circuits #Electronics #DIY , Kinsten PCB

Комментарии

0:10:11

0:10:11

0:12:23

0:12:23

0:05:35

0:05:35

0:10:56

0:10:56

0:10:04

0:10:04

0:04:38

0:04:38

0:06:17

0:06:17

0:10:40

0:10:40

0:12:29

0:12:29

0:45:41

0:45:41

0:04:35

0:04:35

0:12:09

0:12:09

0:06:41

0:06:41

0:44:57

0:44:57

0:40:27

0:40:27

0:11:05

0:11:05

0:08:08

0:08:08

0:08:51

0:08:51

0:05:49

0:05:49

0:00:56

0:00:56

0:18:04

0:18:04

0:34:27

0:34:27

0:07:51

0:07:51

0:11:29

0:11:29