filmov

tv

I Tested The WORST Drill Bits Ever Made!

Показать описание

follow me on instagram: @therealtylertube

My equipment

I Tested The WORST Drill Bits Ever Made!

Testing The WORST Drill Attachments From Amazon!

Best Worst Drill Testing

Dewalt combi,worst drill I ever owned!!!!

Testing the World's Most Hated Tool

I Tested The Worst Gorilla Tag Products

Bro tells the Drill Sergeant what to do

Best Drill (BATTERY POWERED)? Milwaukee vs Dewalt, Makita, Bosch, Festool, Ryobi, Bauer, Ridgid

Best Drill Attachments? Safe or Deadly? Let’s find out!

Big Cat Drill gets testy at LSU

USMC Officer Candidate bumps into Drill Instructor #USMC #OCS #military #training

idk drill remix song and some1 getting sturdy

Why CHEAP Drill Bits are the WORST!

The Worst cordless drill accessory #shorts #fact #omg #funny #lol

$1,000 Snap-On Drill vs World's Strongest: Bosch, M18, Flex, DeWALT

ibell electric ⚡ worst drill machine don't buy 😡

Army Drill Sergeant Rates 11 Boot Camps In Movies And TV | How Real Is It? | Insider

divans drill...the most painful way possible (Hypixel Skyblock)

Worst Drill I've Purchased! So Why Am I Happy I Bought It?

Extreme Drill Durability Test 60,000 PSI Waterjet

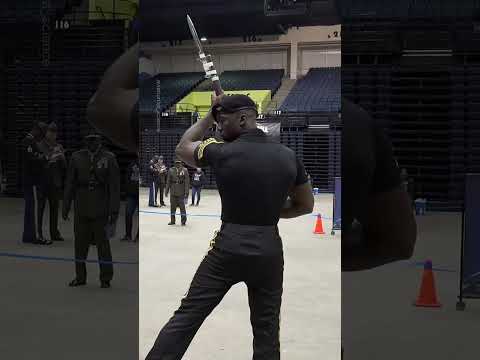

Solo - World Drill Championships

This Hercules 12 Volt Drill is the Best/ Worst!

This Electric Drill Could Kill You, Why? & How To Test

Firefighter - Fast turnout drill 33.87 seconds/JT #shorts

Комментарии

0:34:44

0:34:44

0:24:35

0:24:35

0:07:52

0:07:52

0:00:15

0:00:15

0:14:01

0:14:01

0:05:00

0:05:00

0:00:08

0:00:08

0:16:54

0:16:54

0:13:51

0:13:51

0:06:28

0:06:28

0:00:08

0:00:08

0:00:14

0:00:14

0:07:48

0:07:48

0:00:26

0:00:26

0:14:52

0:14:52

0:00:12

0:00:12

0:20:37

0:20:37

0:15:02

0:15:02

0:12:00

0:12:00

0:12:41

0:12:41

0:00:30

0:00:30

0:00:54

0:00:54

0:04:29

0:04:29

0:00:40

0:00:40